Golf cart lithium batteries transform fleet performance. They swap heavy lead-acid blocks for nimble lithium-ion cells, boosting power density and slashing charge times. Resorts and gated communities, in particular, see fewer downtime headaches and lower maintenance bills when they upgrade.

Grasping How Lithium Batteries Work

Picture two tanks of water: one built from dense brick, the other from sturdy plastic. Both hold the same volume, but the brick tank fills slowly, is prone to leaks, and adds weight stress to its base. A lithium pack works like the plastic tank: it charges faster, remains sealed, and sheds countless pounds of dead weight.

By changing the chemistry, you gain up to 40% more energy density compared to a lead-acid string. Charge cycles drop into a 4–6 hour window, and your cart spends far more time on the course and less in the garage.

- Higher Energy Density: Deeper discharge cycles, extended range.

- Faster Recharges: Idle time cut in half.

- Lightweight Design: Up to 300 pounds shed from the chassis.

- Longer Lifespan: Over 2,000 cycles versus 400–600 cycles for lead-acid.

Key Takeaway: Lithium packs deliver up to 40% better energy density and reduce battery weight by more than 50%.

Benefits For Operators

Consistency under load is crucial when carts haul guests up steep fairways or cover back-to-back tee times. Golf cart lithium batteries hold voltage steadily, so performance doesn’t dip when you need it most.

- 50% Fewer Service Checks: Reduced wear on brakes, suspension, and electrical components.

- Lower Energy Costs: Higher efficiency translates to savings on each charge.

- Improved Guest Experience: Fewer breakdowns and smoother rides across resorts and communities.

Global demand for these batteries is surging, with the market forecast to hit $500 million by 2025 and maintain a 15% CAGR through 2033. Discover more insights about this growth in golf cart lithium battery market research.

It’s also important to review the principles of low voltage electrical systems when planning upgrades, since these batteries and their peripherals operate within that framework.

Real-World Deployment Stories

Firsthand accounts reveal the tangible benefits of switching to lithium technology:

- A beachfront resort swapped 50 lead-acid carts for lithium packs and slashed service costs by 30% during peak season.

- A mountain community cut towing incidents by 40%, thanks to lighter battery weight and more consistent voltage.

- A private golf club maintained steady performance on hot, busy afternoons, boosting member satisfaction.

These stories underline how lithium batteries drive real savings and reliability.

Understanding Environmental Impact

Replacing lead-acid with lithium has significant environmental advantages:

- High Recycling Rates: Many regions reclaim over 90% of lithium cells.

- No Acid Disposal: Eliminates sulfuric acid spill risks and lead contamination.

- Lower Emissions: Extends fleet life with fewer replacements and aligns with stricter clean-energy standards.

Armed with this knowledge, operators can confidently move into the next phase: sizing and compatibility checks for the ideal lithium pack.

Advantages Over Lead Acid Batteries

Imagine a sprinter burning out after one lap while a marathon runner paces steadily over dozens. A lithium golf cart battery behaves like that marathoner—it holds its power longer and charges far more times than a lead-acid pack.

You can run multiple back-to-back rounds without feeling that mid-game voltage dip or rushing to a charging station.

- Up To 2,500 Cycles compared to 400–600 on a lead-acid bank.

- 500 Pounds lighter, easing stress on suspension and chassis.

- Zero Watering Requirements, so no more fluid checks or sulfation worries.

- Stable Voltage under heavy loads, whether you’re up a steep hill or fully loaded.

Feature Comparison Of Lead Acid And Lithium Batteries

Below is a side-by-side look at how these two battery types perform in key areas.

Feature Comparison of Lead Acid and Lithium Batteries

| Feature | Lead Acid Battery | Lithium Battery |

|---|---|---|

| Cycle Life | 400–600 cycles | 2,000+ cycles |

| Weight | 600–800 lbs | 100–300 lbs lighter |

| Maintenance | Regular watering and cleaning | Minimal maintenance, no watering |

| Voltage Stability | Voltage drops as charge depletes | Voltage steady until near full discharge |

| Recharge Time | 8–10 hours | 4–6 hours |

This quick comparison highlights why lithium wins on durability, weight, and convenience.

Dropping 500 pounds from a cart doesn’t just feel light—it translates to smoother turns and less wear on shocks. In fact, a 1,200-pound cart gains an extra 200 pounds of passenger or cargo capacity over lead-acid setups.

“Installing lithium packs at our resort cut downtime in half and made scheduling seamless,” says a fleet manager.

Real-World Examples

At Sunshine Resort, switching to lithium meant golfers played straight through afternoon storms without a single power drop.

Nearby, a gated community fleet increased daily rounds by 20% with no extra charging stops.

Maintenance Simplified

Lead-acid batteries demand regular watering, cleaning, and careful monitoring for sulfation. Lithium packs arrive sealed and ready. No messy acid spills, no built-in capacity loss—just simple wipe-downs to keep terminals pristine.

Getting a handle on how long a lithium pack lasts is key to protecting your investment. For another perspective on battery durability and factors that affect cycle life, check out how long solar batteries last.

The global shift to eco-friendly mobility is driving rapid expansion in golf cart lithium batteries. Analysts valued this market at $708 million in 2024 and see it reaching $794 million by 2025, then climbing to $2.5 billion by 2035 at a 12.1% CAGR. Read the full research on wiseguyreports.com.

Switching to lithium cuts maintenance hours, boosts uptime, and elevates every ride. It’s a clear choice for delivering top performance and cost savings.

Choosing The Right Battery Size And Compatibility

Every golf cart run starts with two questions: how far am I driving today, and will my cart’s electrical system handle the load? Picking the right amp-hour (Ah) rating feels a lot like choosing a gas tank—more capacity stretches your range, but it comes with a higher price tag.

- 200Ah Packs: Ideal for light residential runs, up to 10–15 miles per day

- 300Ah Packs: Perfect for resort circuits covering 15–20 miles daily

- 400Ah Packs: Built for commercial shuttles or LSV routes that exceed 20 miles

For instance, a 200Ah battery on a 12-mile community loop gives you plenty of extra juice for detours and unexpected stops. Plotting your daily route—hills, guest load, accessories—helps nail down the exact size you need.

Estimating Daily Range Requirements

Charting your path in advance prevents surprises once you hit the accelerator. A fully loaded cart climbing a steep incline at 5 mph draws far more energy than coasting on flat ground at 15 mph.

Plan for at least 20% extra capacity to cover headlights, air cooling, and unexpected delays. That cushion keeps you moving without hunting for a charger mid-route.

Key Insight: Giving yourself extra Ah in the tank means fewer mid-route top-ups and more uninterrupted service.

Matching Voltage Systems

Most carts use either 36V or 48V systems—and your choice affects power, cost, and compatibility. A 36V pack usually costs less and integrates easily but tops out on peak performance. Meanwhile, 48V setups deliver stronger torque and faster acceleration, especially under heavy loads.

| System Voltage | Pros | Cons |

|---|---|---|

| 36V | Lower cost, simpler setup | Limited peak power |

| 48V | Higher torque, more efficient | Higher upfront investment |

Don’t forget the BMS: it must match your cart’s voltage, support safe startup sequences, and balance cells during charging. For a deeper dive, check out the best lithium battery for golf cart guide at Solana EV.

In the U.S., golf cart lithium batteries are on track to surpass $1 billion in sales by 2028, driven by a 5–7% CAGR through 2030. Explore the full golf cart lithium battery market analysis for more insights.

Verifying Physical Fit And Connector Types

Space and wiring details can make or break an installation—measure your battery bay carefully, note terminal layouts, and confirm cable lengths. Even a slight mismatch can turn a swap into a full-day headache.

Pay special attention to BMS harness compatibility: it should support temperature sensors, voltage balancing, and emergency shutdown routines.

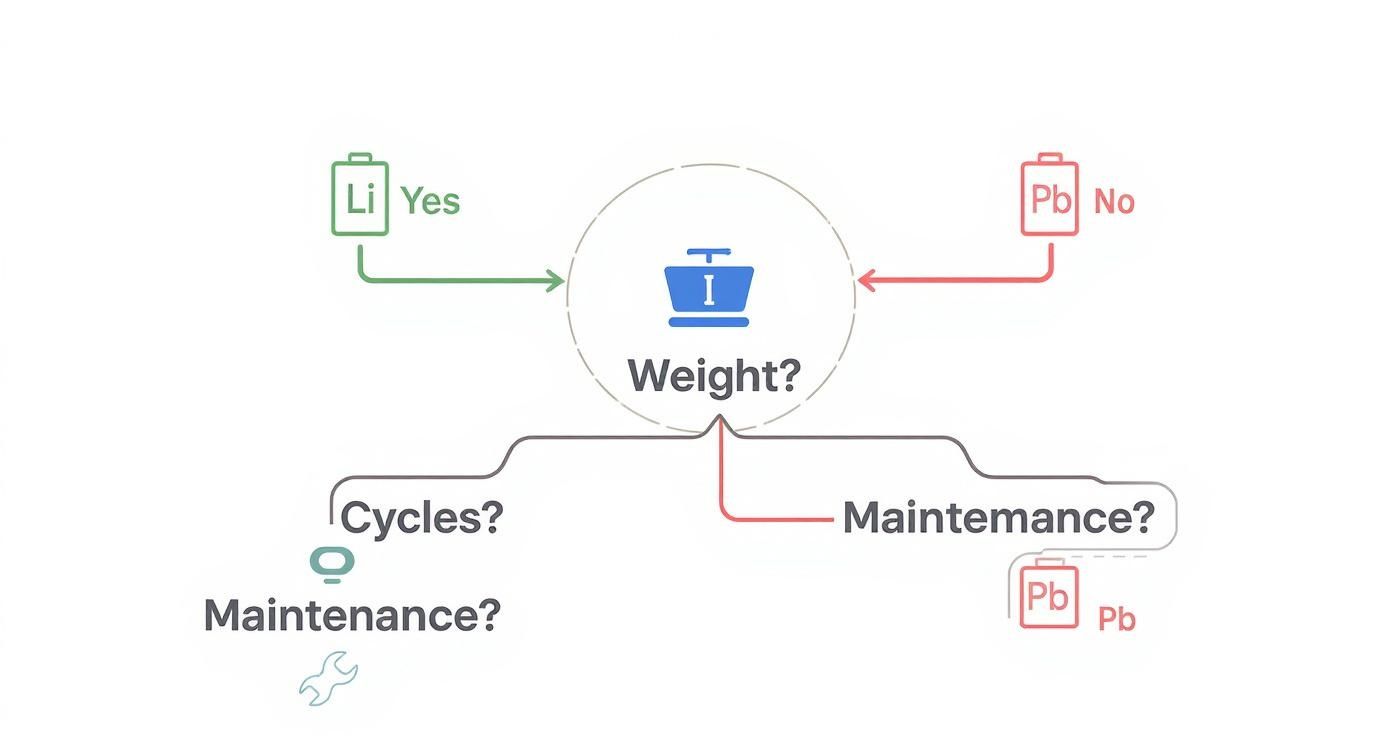

This decision tree breaks down weight, cycle life, and maintenance factors—if you prize lower mass, longer lifecycles, and minimal upkeep, lithium clearly outperforms lead-acid.

Decision Paths For Common Scenarios

Choose the scenario that matches your needs:

- Residential Errands: 36V + 200–300Ah pack for daily community loops

- Resort Fleets: 48V + 300–400Ah pack to handle back-to-back shuttle runs

- Street-Legal LSVs: 48V + 400Ah+ battery with a robust BMS and highway-grade connectors

Ultimately, dialing in the right Ah, voltage, size, and BMS features sets you up for seamless operation and satisfied passengers on every trip.

Understanding Technical Specifications

Specs on battery data sheets can feel like a foreign language. Amp-hours, kilowatt-hours and C-rate jump out at you, yet their real meaning stays hidden. Let’s turn those confusing figures into clear ideas with everyday analogies.

Think of Amp-Hours (Ah) as the size of your fuel tank. A 300Ah pack holds more “juice” than a 200Ah option, translating to longer range between charges.

Next up, Kilowatt-Hours (kWh) represent the total energy you carry. Imagine it as the total volume of fuel in that tank. A 14.4 kWh battery can deliver 1 kW of power for roughly 14 hours.

Finally, the C-Rate shows how fast you can fill or empty that tank. It’s like the width of the hose at a gas pump. A 1C rate means a full charge or discharge in one hour; bump it to 2C, and you halve that time.

Higher C-rates let you charge swiftly without overheating and give your cart extra punch on hills. In practice, that means quicker turnarounds between rounds and smoother climbs.

Key Specifications Explained

- Amp-Hours (Ah): Available capacity; higher Ah equals more runtime.

- Kilowatt-Hours (kWh): Total stored energy; use kWh when comparing overall power.

- C-Rate: Maximum safe charge/discharge speed; crucial for fast turnaround and heavy loads.

- Cycle Life: Number of full discharge cycles before capacity drops below 80%.

- BMS Integration: Monitors cell health, temperature, and balance. Learn more in our guide on what is a battery management system.

When you line up spec sheets from different brands, you get a quick snapshot of performance. Here’s a side-by-side look at two popular golf cart lithium packs:

| Metric | VoltMax 300Ah Pack | EcoPower 250Ah Pack |

|---|---|---|

| Capacity (Ah) | 300Ah | 250Ah |

| Energy (kWh) | 14.4 kWh | 12.0 kWh |

| Charge Rate (C) | 1C | 2C |

| Discharge Rate (C) | 1.5C | 1.2C |

| Cycle Life | 2,500 cycles | 2,000 cycles |

| Weight | 120 lbs | 105 lbs |

Key Takeaway A higher C-rate pack charges faster but may trade some cycle life and add cost.

Case Study Comparing Performance

Consider two real-world examples:

A 300Ah pack at 1C charges at 300A, wrapping up in about 1 hour.

Meanwhile, a 250Ah pack at 2C pushes 500A, finishing in roughly 30 minutes.

- Charge Time: 300Ah @ 1C = 1 hour; 250Ah @ 2C = 0.5 hour

- Thermal Impact: Slower C-rate reduces heat buildup

- Longevity: Lower charge currents typically extend cycle life

For operations where every minute counts, a high C-rate battery shines. On the other hand, if you prioritize cooler operation and extended lifespan, a moderate C-rate makes more sense.

Internal components like the BMS ensure cells charge evenly and prevent issues. Always follow manufacturer guidelines for charge rates and temperature limits to protect your investment over the long term.

Decoding battery specs empowers you to match pack performance to your fleet’s needs. Align Ah for extended loops, robust C-rate for quick turnarounds, and balanced kWh for daily throughput. By combining spec-sheet analysis with real-world testing, you’ll pick a battery that delivers on range, charging rhythm, and load demands.

Now you’re ready to shop.

Installation And Maintenance Steps

Fitting a lithium battery into your golf cart demands focus and the right tools. A precise installation keeps the battery healthy and sidesteps costly hiccups. Miss the specified torque settings or mix up BMS connections, and you risk system alerts or faults.

Safety Precautions

Before you begin, suit up properly.

- Wear acid-resistant gloves to protect your hands around terminals.

- Put on safety goggles in case of sparks.

Next, prevent electrical shorts by donning insulating mats and boots. Always keep a fire extinguisher rated for electrical fires within arm’s reach. Finally, double-check that your workspace is dry and free of metal shavings.

Removing The Old Battery

Shut off the cart and take out the key. Start by disconnecting the negative cable, then the positive—this order avoids sparks and potential shorts. Label each wire so reconnecting later is straightforward.

- Securely wear all PPE listed above.

- Loosen terminal bolts to the manufacturer’s torque specs.

- Lift the old battery pack out with two people or a hoist.

- Inspect the tray and harness for corrosion or damage.

- Clean contact surfaces using a wire brush and electrical cleaner.

“Proper removal of old batteries reduces the risk of shorts and BMS errors.”

Installing The New Lithium Pack

Slide the new lithium module into place, aligning the mounting holes exactly. Hand-tighten the bolts, then torque them to 8–10 Nm with a calibrated wrench.

- Ensure the pack voltage matches your cart system (36V or 48V).

- Connect the BMS harness by matching color-coded plugs.

- Confirm BMS firmware is compatible with your charger protocol.

- Route wiring away from moving parts and heat sources.

- Secure cables with zip ties and add abrasion protection.

A snug mount and tidy wiring set the stage for reliable performance under load.

Routine Maintenance

A regular check-up keeps your battery in peak shape. Every 100 hours, perform a BMS health scan and balance cells to keep voltages even.

- Inspect terminals quarterly and retorque loose connections.

- Wipe contact surfaces with a lint-free cloth and isopropyl alcohol.

- Run cell-balancing mode via BMS or your charger software monthly.

- Update BMS firmware when critical patches are released.

- Log every maintenance activity to maintain warranty coverage.

Consistent cleaning and software updates help you avoid unexpected downtime.

Troubleshooting Common Issues

Even with diligent care, problems can pop up. Here are quick fixes for the most frequent faults:

- False BMS Alarms: Reseat harnesses and tighten connectors.

- Error Code 12: Temperature sensor out of range—recalibrate.

- Cart Not Starting: Check the main relay signal and BMS status LED.

- Unexpected Shutdowns: Inspect individual cell voltages and run a full-cycle test.

- Slow Charging: Verify charger settings match the battery’s C-rate and voltage.

Tip: Keep a spare fuse and quick-release connectors for field repairs.

Document every error code and your troubleshooting steps. When in doubt, share logs with Solana EV support.

Best Practices For Long Life

Think of your battery like a delicate instrument—it prefers stable conditions. Store carts in a climate-controlled area and keep state of charge between 20% and 80% during long layups.

- Schedule summer and winter storage cycles to match seasonal use.

- Use a maintenance charger to apply a gentle float charge when idle.

- Avoid temperatures below 32°F or above 105°F.

- Rotate battery loads by swapping carts in larger fleets.

- Review BMS logs quarterly to spot gradual performance drift.

- Check cable insulation annually and replace any worn sections before they cause issues.

Following these steps maximizes your lithium battery’s lifespan, cuts downtime, and delivers a solid return on investment for resorts, dealerships, and gated communities.

Charging Infrastructure And Best Practices

Building a robust charging setup is the backbone of any dependable golf cart fleet. Matching charger capabilities to your operation prevents bottlenecks and keeps downtime to a minimum. You’ll generally choose between onboard units that live inside each cart or offboard stations that serve several vehicles at once.

- Onboard Chargers attach neatly within the cart frame and deliver 1–2 kW for a steady, overnight refill.

- Offboard Chargers sit at a centralized bay, pushing 5 kW+ to multiple carts in rapid succession.

- Temperature Compensation features automatically tweak voltage in extreme hot or cold conditions, preserving battery health.

For a single residential cart, a 2 kW onboard charger hits the sweet spot between cost and convenience. Larger commercial operations often lean on 5 kW+ offboard stations to top up packs in under two hours, keeping fleets on the move.

Charger Types And Loading

Onboard chargers let you plug in wherever, making them ideal for spread-out resorts or private properties. They do take longer—think overnight—so plan your idle periods accordingly.

Offboard chargers require a fixed footprint but cut charging windows by about 50%, perfect for tight turnaround schedules. That trade-off—mobility versus throughput—drives many fleet managers’ decisions.

Battery longevity hinges on a three-phase charge profile:

- Bulk Stage pushes maximum current until the pack hits 80% capacity.

- Absorption Stage holds voltage steady and eases the current for cell balancing.

- Float Stage drips in a low current to maintain a full charge without stress.

Learn more in our guide on charging golf carts for detailed charger-matching tips.

Layout Planning And Electrical Requirements

Design your charging bays with at least 3 ft of clearance on each side to keep technicians safe and reduce fire risk. Proper ventilation—whether natural or forced—prevents heat build-up and clears any hydrogen that might escape during charging.

When sizing your panel, add a 25% safety margin to the total kilowatt load. This headroom prevents nuisance trips when multiple chargers fire up at once.

| Component | Clearance | Ventilation Rate |

|---|---|---|

| Small Cart Bay | 3 ft | 500 CFM |

| Fleet Station | 5 ft | 1000 CFM |

| Service Bay | 4 ft | 750 CFM |

Resorts often opt for three-phase power to feed 5 kW+ offboard chargers, while dealerships might need 200A panels to handle several units. Smart electrical planning means fewer disruptions during peak charging windows.

Scheduling And Emergency Protocols

High-season rotation thrives on staggered schedules: charge one third of your fleet in the morning, another third before lunch, and the last segment in the afternoon. For carts in long-term storage, a monthly float charge to 50% state of charge wards off deep discharge damage.

- Emergency Charging Protocol

- Deploy a portable 2 kW charger to critical carts on demand.

- Prioritize frontline vehicles based on usage data and BMS alerts.

- Keep extra cables and adapters on hand for quick swaps.

“A clear charging schedule reduced downtime by 30% during our busiest months,” says a resort fleet manager.

In regions with severe temperature swings, a climate-controlled charging room set between 50°F and 77°F keeps batteries happy. Add heating or cooling units near the chargers to stave off thermal stress. Finally, schedule regular inspections of temperature sensors and BMS logs to confirm automatic compensation kicks in when needed.

- Temperature Control Tips

- Keep ambient temperatures within manufacturer-recommended ranges.

- Post clear signage outlining charger operation zones and hazard areas.

- Inspect cables, connectors, and breakers on a quarterly basis.

Your Questions, Answered

How Long Will My Lithium Batteries Really Last Compared to Lead-Acid?

This is one of the biggest questions we get, and the difference is night and day. A quality lithium battery will give you 2,000 to 2,500 full charge cycles before its capacity even thinks about dipping below 80%.

Your old lead-acid batteries? You're lucky to get 400 to 600 cycles out of them. That means you could be swapping out lead-acid packs every 3 years, while a lithium setup can easily last up to a decade. Think about the reduced downtime and replacement costs across an entire fleet.

To get the most out of them, a little care goes a long way.

- Try to keep the charge level between 20–80% for daily use.

- Avoid letting them drain completely below 20%. It really helps extend the cycle count.

- Let the Battery Management System (BMS) do the heavy lifting—use its alerts to know exactly when it's time to plug in.

Following these simple habits can add years to your battery’s life and squeeze every drop of value from your investment.

What's the Best Way to Store Batteries in the Off-Season?

When your carts are sitting idle for long stretches, you don't want the batteries to slowly die. The key is to prevent a deep discharge. The sweet spot for storage is a 50% state of charge. Find a dry, climate-controlled spot to park them.

A few simple seasonal routines will ensure they're ready to roll when you are:

- Check on them once a month. A quick hook-up to a maintenance charger for a gentle top-up is all they need.

- Keep them out of extreme temperatures. Try to avoid storing them anywhere below 32°F or above 77°F.

- It's also a good idea to inspect the terminals for any corrosion and apply a little dielectric grease for protection.

This small amount of effort protects your investment and guarantees a smooth start to your peak season.

How Do They Handle Extreme Heat and Cold?

One of the best things about lithium chemistry is its resilience. It handles temperature swings far better than lead-acid ever could. That said, performance isn't totally immune to extreme conditions.

For instance, trying to charge a battery when it's over 95°F can speed up its aging process. On the flip side, charging below 32°F can be slow going, as the battery won't accept the charge as readily. This is where your BMS becomes your best friend, allowing you to monitor temps and adjust accordingly.

- At a comfortable room temperature, don't charge any higher than 54.6V.

- If you're charging in the heat (above 95°F), dial back the voltage by about 0.005V per cell for each degree over.

- In the winter, make sure the batteries warm up to at least 50°F before you start charging.

These adjustments are crucial for preserving battery capacity and avoiding unnecessary thermal stress.

Are There Special Rules for Shipping Lithium Packs?

Absolutely. Transporting lithium batteries isn't as simple as throwing them in a truck. You have to follow specific UN and IATA regulations to do it safely and legally. The two most important things to remember are that packs must be shipped at no more than a 30% state of charge and must be in UN-certified packaging.

Here's a quick cheat sheet:

| Requirement | Details |

|---|---|

| State of Charge | Must be 30% or less. |

| Packaging Class | Use a UN3480-rated, strong outer box. |

| Labeling | Clearly mark it "Lithium Ion Batteries in Equipment". |

| Documentation | Always include the Safety Data Sheet and proper shipper’s papers. |

"Always ship golf cart lithium battery packs with proper UN labels and a clear handling mark," advises a logistics manager.

Getting this right from the start ensures your batteries get where they're going without any hold-ups or safety issues.

What Should I Look for in a Warranty and Dealer Support?

A good warranty tells you a lot about the manufacturer's confidence in their product. Most reputable brands offer coverage for 5–10 years or a set number of cycles, like 2,000. But the devil is in the details.

Make sure you check the fine print for these key things:

- Prorated replacements that kick in after the initial term.

- BMS health checks included as part of regular dealer service.

- Clear-cut conditions on what voids the warranty (like consistent overheating or abuse).

- Access to cycle reporting and analytics so you can actually track your fleet's performance.

Some companies also offer extended warranty plans that cover things like accidental damage or guarantee a certain power capacity over time. These can be well worth the small extra cost for the peace of mind they provide.

Don't forget about the human element, either. A great dealer provides training, helps you set up maintenance schedules, and can get you parts quickly. Before you buy, ask about replacement lead times and any hidden service fees. A strong partnership with your dealer means faster solutions and less stress when something eventually goes wrong.

Have more questions or need advice specific to your operation? Reach out today to Solana EV’s experts for tailored recommendations.

Ready to elevate your fleet’s performance with a reliable golf cart lithium battery? Visit Solana EV to explore premium solutions.

Nice Post.

269792 169504I consider something really special in this website . 199571