Transitioning to an electric vehicle (EV) fleet represents a significant move towards sustainability and reduced operating costs. However, effectively managing these advanced assets demands a new playbook. Unlike their internal combustion counterparts, EVs introduce unique operational variables, including battery health monitoring, complex charging logistics, and specialized maintenance protocols that are critical to master.

Successfully navigating these challenges is the key to unlocking the full return on your investment and achieving peak performance. This guide cuts through the complexity, providing a comprehensive roundup of essential fleet management best practices tailored specifically for the modern EV landscape.

We will deliver actionable strategies designed to build a smarter, more efficient, and future-proof operation. You will learn how to implement advanced telematics for real-time tracking, optimize charging schedules to maximize battery lifespan, and establish proactive maintenance routines that prevent costly downtime. The following sections offer a clear roadmap, providing the specific insights needed to enhance the performance and reliability of your commercial or personal EV fleet, ensuring you are equipped to lead in this new era of transportation.

1. Implement GPS Fleet Tracking and Telematics

GPS fleet tracking and telematics systems are the cornerstone of modern fleet management best practices. These platforms combine GPS technology with onboard vehicle diagnostics to provide a real-time, comprehensive view of your entire fleet. The system collects and transmits critical data, including vehicle location, speed, fuel consumption, idle time, and diagnostic trouble codes. This information empowers managers to move from reactive problem-solving to proactive, data-driven optimization.

By analyzing this data, you gain unparalleled insight into operational efficiency and driver behavior. You can identify unauthorized vehicle use, eliminate inefficient routes, monitor for harsh braking or rapid acceleration, and track engine health to pre-empt costly breakdowns. This level of oversight is crucial for reducing operational costs and enhancing safety across your fleet.

Real-World Impact and Implementation

The benefits of telematics are not just theoretical; they are proven by major industry players. UPS, for example, leverages its ORION system to save an estimated 100 million miles annually through advanced route optimization. Similarly, food distribution giant Sysco reduced its fuel costs by a remarkable 13.6% after adopting a telematics solution. These examples highlight how granular data can translate into significant financial and operational gains.

To successfully integrate this technology, consider these actionable steps:

- Start Small: Launch a pilot program with a small subset of your vehicles to identify potential challenges and demonstrate ROI before a full-scale deployment.

- Involve Drivers: Include drivers in the selection and implementation process. Their buy-in is critical for adoption and helps frame the technology as a tool for safety and support, not just surveillance.

- Focus on Coaching: Use driver behavior data to create a positive coaching program. Instead of punishing poor habits, focus on rewarding safe driving and providing constructive feedback for improvement.

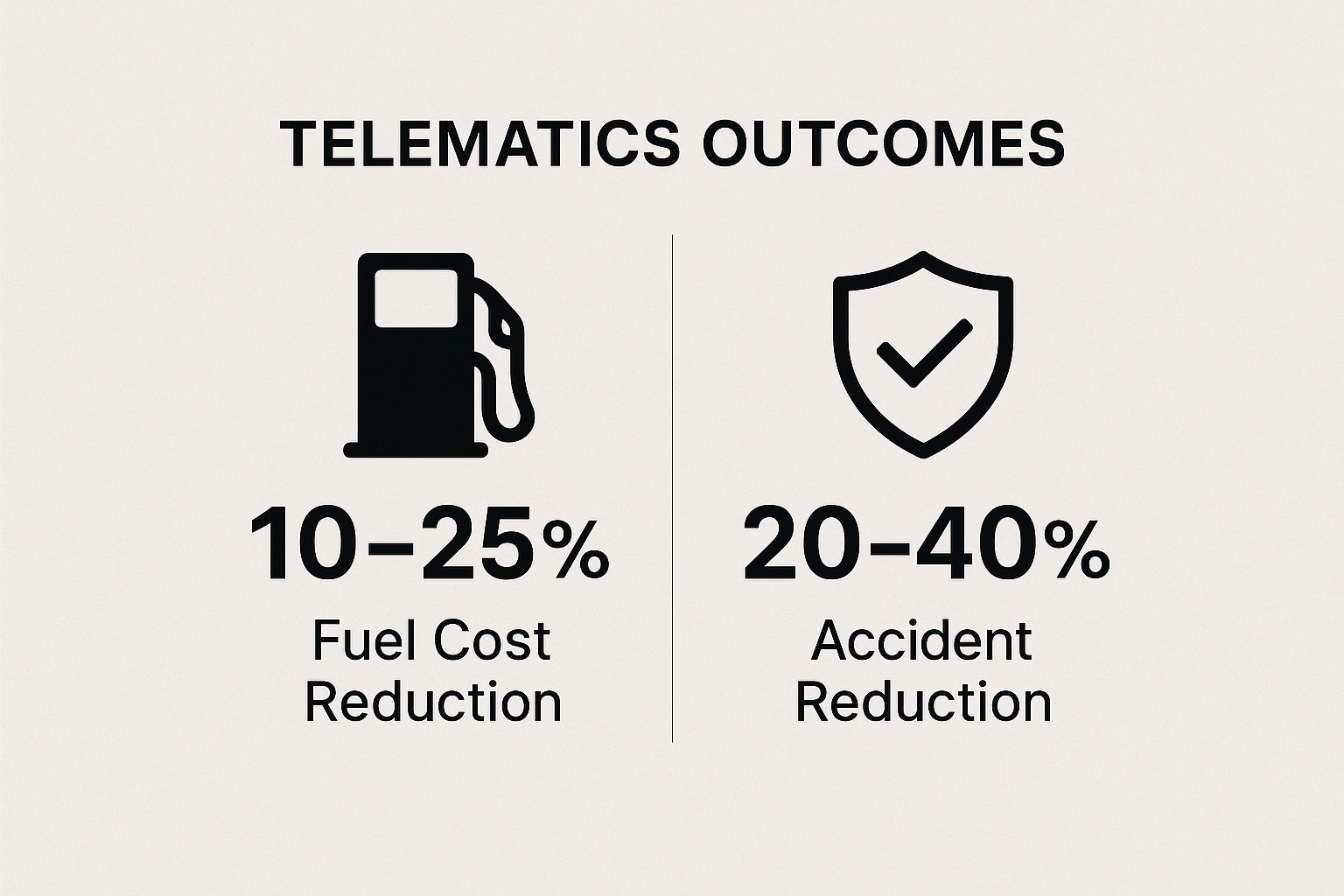

The following infographic illustrates the significant cost and safety improvements that telematics can deliver.

These figures show that implementing a telematics system can directly lead to major reductions in both fuel expenditure and accident frequency. Even for smaller, specialized fleets like those found in resorts or gated communities, the principles of GPS tracking can yield powerful results. For a deeper look into this technology, you can explore the applications of golf cart GPS tracking.

2. Establish Preventive Maintenance Programs

Establishing a robust preventive maintenance program is another fundamental fleet management best practice. Instead of reacting to costly and disruptive breakdowns, this approach involves scheduling regular vehicle inspections, servicing, and component replacements based on predefined triggers like mileage, time intervals, or hours of operation. This proactive strategy is designed to maximize vehicle uptime, extend asset lifespan, and significantly reduce the total cost of ownership by addressing minor issues before they escalate into major failures.

By shifting from a reactive to a proactive maintenance model, fleet managers can better predict costs, improve vehicle reliability, and enhance safety. A well-executed program ensures that every vehicle in the fleet consistently operates at peak performance, which directly impacts fuel efficiency, driver safety, and operational continuity. This systematic approach is essential for maintaining a healthy, dependable, and cost-effective fleet.

Real-World Impact and Implementation

The effectiveness of preventive maintenance is demonstrated by leading logistics and transportation companies. FedEx Ground, for instance, utilizes predictive analytics to fine-tune its maintenance schedules, resulting in a reported 12% reduction in maintenance costs. Similarly, Ryder System Inc. provides programs that help its clients achieve over 99% vehicle availability, showcasing how proactive servicing minimizes downtime and keeps businesses moving. These examples prove that a structured maintenance plan delivers substantial operational and financial advantages.

To implement a successful preventive maintenance program, consider these actionable steps:

- Follow Manufacturer Guidelines: Use the manufacturer's recommended maintenance schedule as your baseline, but be prepared to adjust it based on your fleet’s specific usage patterns, operating conditions, and vehicle age.

- Empower Drivers with Pre-Trip Inspections: Implement mandatory daily pre-trip inspections. Drivers are the first line of defense in identifying potential issues like low tire pressure or fluid leaks before they become serious problems.

- Maintain Detailed Records: Keep meticulous maintenance records for every vehicle. This data not only helps track costs per asset to identify problematic vehicles but also significantly boosts resale value by demonstrating a history of proper care.

A well-documented maintenance history is crucial, whether you are managing a large commercial fleet or a smaller, specialized one. For a detailed guide on creating such a plan, you can find more information about proactive golf cart maintenance.

3. Optimize Route Planning and Scheduling

Route optimization is one of the most impactful fleet management best practices, using advanced software and real-time data to calculate the most efficient paths for your vehicles. These systems analyze numerous variables, including traffic conditions, delivery windows, vehicle capacity, driver schedules, and fuel or energy consumption. The goal is to dramatically reduce total mileage, cut operational costs, and improve service delivery times. By moving beyond simple turn-by-turn directions, you can create dynamic schedules that maximize productivity for every vehicle in your fleet.

This strategic approach transforms route planning from a manual, often inefficient task into an automated, highly optimized process. The software can create multi-stop routes that are not only the shortest but also the most logical and cost-effective. For fleets of any size, from national delivery services to local resort maintenance crews, this means less time on the road, lower fuel and energy expenses, and an increased capacity to serve more customers or complete more tasks each day.

Real-World Impact and Implementation

The benefits of sophisticated routing are clear across industries. UPS famously uses its ORION (On-Road Integrated Optimization and Navigation) system to save an estimated 10 million gallons of fuel annually by trimming just one mile per driver per day. Similarly, DHL reduced its delivery costs by 15% after implementing route optimization software, showcasing significant financial returns. These examples prove that strategic planning directly translates into massive operational savings and enhanced efficiency.

To effectively integrate route optimization, consider these actionable steps:

- Analyze Historical Data: Begin by reviewing past route and delivery data to identify existing inefficiencies, common delays, and areas for immediate improvement.

- Involve Your Drivers: Tap into your drivers' on-the-ground knowledge. They often have valuable insights into local traffic patterns, customer-specific requirements, and access issues that software alone might miss.

- Prioritize Customer Needs: Configure your optimization software to account for specific customer delivery windows and preferences, ensuring that efficiency gains do not come at the expense of service quality.

- Continuously Monitor and Adjust: Regularly review route performance against key performance indicators (KPIs) like on-time delivery rates and cost-per-stop. Use this data to refine and update your routing strategies over time.

4. Implement Driver Safety and Training Programs

Technology and data are powerful, but the human element remains the most critical factor in fleet safety and efficiency. Comprehensive driver safety and training programs are essential fleet management best practices because they directly address the root cause of most accidents and inefficiencies: driver behavior. These programs go beyond a one-time orientation, creating a continuous culture of safety through initial training, ongoing education, performance monitoring, and targeted coaching.

A robust program covers everything from defensive driving techniques and company policies to regulatory compliance and vehicle-specific handling. By investing in your drivers' skills and knowledge, you not only reduce accidents, liability, and insurance premiums but also improve fuel efficiency, decrease vehicle wear and tear, and boost employee morale. This proactive approach turns your drivers into your greatest safety asset.

Real-World Impact and Implementation

The effectiveness of formal safety programs is well-documented by industry leaders. Walmart’s rigorous driver training has led to its fleet logging over 1 billion miles without a preventable fatality. Similarly, Schneider National's comprehensive safety program successfully reduced accidents by 35% over a five-year period. These examples prove that a systematic commitment to driver education yields tangible, life-saving results and significant operational savings.

To build a successful safety and training program, consider these actionable steps:

- Use Data for Personalization: Leverage telematics data to identify specific risky behaviors like harsh braking or speeding. This allows you to tailor training to individual driver needs rather than using a one-size-fits-all approach.

- Implement Peer Mentoring: Pair new hires or drivers needing improvement with experienced, high-performing veterans. This peer-to-peer model fosters camaraderie and provides practical, real-world guidance.

- Provide Consistent Feedback and Recognition: Don't just focus on mistakes. Create a formal system to regularly recognize and reward safe driving records, creating positive reinforcement and motivating the entire team.

Effective training is fundamental to safe operations for any vehicle type, from large trucks to smaller electric carts. To see how these principles apply to specialized fleets, you can explore the essentials of golf cart safety training.

5. Monitor and Control Fuel Costs

Fuel cost management is a critical pillar of effective fleet management best practices, as fuel often accounts for 20-30% of total operating expenses. This practice involves systematically monitoring, analyzing, and controlling fuel consumption across every vehicle. By leveraging tools like fuel cards, consumption tracking software, and driver training programs, managers can gain precise control over this significant and often volatile expense, directly boosting the company's bottom line.

The core principle is to transform fuel from an uncontrollable variable into a managed asset. Tracking every gallon allows you to identify anomalies, such as fuel theft, inefficient driving habits like excessive idling, or vehicles that require maintenance. This granular oversight is essential for making informed decisions that reduce waste and enhance overall operational efficiency, regardless of fleet size.

Real-World Impact and Implementation

Major corporations demonstrate the profound impact of diligent fuel management. Frito-Lay, for instance, saved an estimated $40 million annually through a comprehensive program that included route optimization and vehicle modifications. Similarly, XPO Logistics improved its fuel efficiency by an impressive 18% by using telematics data to coach drivers on fuel-saving techniques. These successes underscore how strategic fuel monitoring translates into substantial financial savings.

To implement a robust fuel management strategy, consider these actionable steps:

- Utilize Fuel Cards: Implement a fuel card program with providers like WEX or Voyager. These cards provide detailed transaction data, limit purchase types, and help prevent unauthorized spending.

- Train for Efficiency: Develop a driver training program focused on fuel-efficient behaviors such as smooth acceleration, maintaining optimal speeds, and reducing idle time.

- Set Clear Targets: Establish specific fuel efficiency targets (e.g., miles per gallon) for different vehicle types or routes and regularly track performance against these benchmarks.

- Maintain Vehicle Health: Ensure vehicles adhere to a strict preventive maintenance schedule, as well-tuned engines, properly inflated tires, and clean filters directly impact fuel economy.

6. Leverage Fleet Management Software and Data Analytics

While GPS tracking provides raw data, dedicated fleet management software is the brain that turns this information into actionable intelligence. These comprehensive platforms are a cornerstone of modern fleet management best practices, integrating multiple data sources like telematics, maintenance logs, driver information, and financial records. This unified dashboard provides complete visibility and control, empowering managers to optimize every facet of their operation through data analytics.

By centralizing information, these systems eliminate data silos and automate complex reporting. You can track total cost of ownership (TCO) per vehicle, monitor compliance, schedule preventative maintenance, and manage driver performance all from a single interface. This holistic approach moves fleet oversight from a series of disjointed tasks to a strategic, data-driven function essential for maximizing efficiency and profitability.

Real-World Impact and Implementation

The transformative power of this software is evident across industries. Republic Services utilizes Geotab to optimize complex waste collection routes, reducing fuel consumption and improving service times. Likewise, ServiceMaster coordinates over 3,000 service vehicles with fleet software, ensuring rapid dispatch and efficient job completion. These examples prove that a robust software platform can deliver significant operational enhancements regardless of fleet size or function.

To successfully implement fleet management software, follow these actionable steps:

- Define Clear Objectives: Before selecting a platform, clearly outline your goals. Are you focused on reducing fuel costs, improving maintenance scheduling, or enhancing driver safety? Your objectives will guide your choice.

- Prioritize Integration: Ensure the software can seamlessly integrate with your existing business systems, such as accounting, payroll, and HR platforms, to create a truly connected operational ecosystem.

- Provide Comprehensive Training: A powerful tool is only effective if your team knows how to use it. Invest in thorough training for managers, dispatchers, and drivers to ensure full adoption and maximize your return on investment.

- Analyze Data Regularly: Schedule regular reviews of the data and key performance indicators (KPIs). Use these insights to identify trends, pinpoint areas for improvement, and make informed strategic decisions for your fleet.

7. Develop Strategic Vehicle Lifecycle Management

Strategic vehicle lifecycle management is one of the most critical fleet management best practices for long-term financial health. This approach involves optimizing every phase of a vehicle's life, from acquisition and operation to maintenance and eventual disposal. By systematically analyzing factors like depreciation, running costs, and resale value, managers can pinpoint the exact moment when a vehicle becomes more expensive to keep than to replace. This data-driven strategy ensures you maximize vehicle utility while minimizing the total cost of ownership (TCO).

Instead of relying on arbitrary timelines or mileage markers, this methodology uses comprehensive data to guide replacement decisions. It considers the rising maintenance expenses of aging vehicles against the depreciation costs of new ones, creating a clear financial picture. This prevents fleets from holding onto assets that drain resources or disposing of them prematurely, thereby maximizing the return on every vehicle investment.

Real-World Impact and Implementation

The financial benefits of a well-executed lifecycle strategy are substantial. Enterprise Fleet Management, for example, consistently helps its clients achieve up to 20% cost savings through lifecycle optimization. Similarly, the City of Los Angeles reduced its fleet costs by a staggering $12 million by right-sizing its fleet and implementing a strategic lifecycle plan. These outcomes demonstrate how shifting from a reactive to a proactive replacement schedule directly impacts the bottom line.

To successfully implement this strategy, consider these actionable steps:

- Track Everything: Meticulously record all vehicle-related costs from the initial purchase price to fuel, maintenance, insurance, and final disposal value. This complete financial history is the foundation of TCO analysis.

- Establish Optimal Cycling: Use industry benchmarks, residual value guides, and your own historical data to determine the ideal replacement point for different vehicle types within your fleet.

- Plan Disposal Strategically: Work with remarketing specialists or use auction platforms to ensure you receive the highest possible residual value for your retired assets, which can then be reinvested into new vehicles.

Moreover, a key part of managing these cycles involves handling numerous agreements. Understanding top contract management best practices is crucial for effectively negotiating leases, purchases, and service contracts.

8. Ensure Regulatory Compliance and Documentation

Navigating the complex web of regulations is a critical component of effective fleet management best practices. This involves strict adherence to all federal, state, and local laws governing commercial vehicle operations, including Department of Transportation (DOT) requirements, environmental standards, and safety protocols. Maintaining meticulous documentation and compliance protects your organization from steep fines, legal liabilities, and operational shutdowns while reinforcing your reputation as a responsible operator.

This practice is not merely about avoiding penalties; it is about establishing a foundation of safety and professionalism. Proper compliance ensures that vehicles are safely maintained, drivers are qualified and operating within legal limits, and all necessary records are readily available for audits. For fleets of all sizes, from national trucking companies to local resort transportation, a proactive compliance strategy is indispensable for long-term sustainability and risk management.

Real-World Impact and Implementation

The commitment to compliance has a clear, positive impact on major industry players. C.R. England, for instance, maintains an exceptional 99.8% compliance rate through comprehensive internal programs, showcasing operational excellence. Similarly, Old Dominion Freight Line has consistently achieved top DOT safety ratings by making regulatory adherence a core part of its business model. These examples prove that a focus on compliance directly correlates with enhanced safety and a stronger market position.

To build a robust compliance framework, consider these actionable steps:

- Stay Informed: Regularly engage with industry associations like the American Trucking Associations (ATA) and monitor updates from bodies like the Federal Motor Carrier Safety Administration (FMCSA) to stay ahead of regulatory changes.

- Leverage Technology: Implement digital systems, such as those offered by J.J. Keller & Associates, to automate the tracking of driver hours, vehicle inspections, and other critical documentation.

- Conduct Internal Audits: Perform regular, scheduled audits of your compliance processes to identify and correct potential issues before they become serious violations. This proactive approach is far more effective than reacting to an official audit.

- Prioritize Training: Ensure all drivers and administrative staff are thoroughly trained on their specific compliance responsibilities and understand the importance of accurate record-keeping.

Fleet Management Best Practices Comparison

| Strategy | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Implement GPS Fleet Tracking and Telematics | Medium to High 🔄🔄 | Moderate to High ⚡ | Fuel cost reduction 10–25%, accident reduction 20–40% 📊 | Real-time monitoring, proactive maintenance, safety improvement | Comprehensive data, safety, routing optimization |

| Establish Preventive Maintenance Programs | Medium 🔄 | Moderate ⚡ | Reduces breakdowns by 70%, extends vehicle life 20–30% 📊 | Scheduled maintenance, asset longevity, warranty compliance | Reduces downtime, cost savings, safety |

| Optimize Route Planning and Scheduling | High 🔄🔄 | Moderate to High ⚡ | Fuel cost reduction 10–20%, delivery capacity +15–25% 📊 | Logistics, delivery efficiency, customer satisfaction | Increased capacity, reduced emissions, efficiency |

| Implement Driver Safety and Training Programs | Medium 🔄 | Moderate ⚡ | Accident reduction 20–50%, improved retention 📊 | Driver risk reduction, regulatory compliance, safety culture | Lower insurance costs, safer fleet, compliance |

| Monitor and Control Fuel Costs | Medium 🔄 | Moderate ⚡ | Fuel cost reduction 15–25%, theft prevention 📊 | Fuel expense management, sustainability efforts | Cost control, detailed reporting, theft reduction |

| Leverage Fleet Management Software and Analytics | High 🔄🔄 | High ⚡ | Improved operational visibility, automation 📊 | Comprehensive fleet management, data integration | Data-driven decisions, scalability, reduced admin burden |

| Develop Strategic Vehicle Lifecycle Management | High 🔄🔄 | Moderate to High ⚡ | Fleet cost reduction 15–25%, improved budgeting 📊 | Asset management, cost control, replacement planning | Optimized TCO, reliable fleet, financial planning |

| Ensure Regulatory Compliance and Documentation | Medium to High 🔄🔄 | Moderate ⚡ | Avoids fines, reduces liability, maintains permits 📊 | Legal compliance, multi-jurisdiction operations | Risk mitigation, safety improvements, authority maintenance |

Driving Your Fleet Forward with Intelligent Management

Navigating the complexities of modern fleet operations requires more than just keeping vehicles on the road; it demands a strategic, data-driven approach. The fleet management best practices detailed throughout this guide, from implementing advanced telematics to establishing robust preventive maintenance schedules, are not isolated tactics. Instead, they are interconnected components of a comprehensive system designed to drive efficiency, enhance safety, and maximize profitability. By embracing these strategies, you shift from a reactive management style, where you fix problems as they arise, to a proactive one, where you anticipate challenges and optimize performance continuously.

The journey toward operational excellence is built on a foundation of actionable data and consistent execution. Leveraging GPS tracking and telematics provides the real-time visibility needed for optimized routing and fuel cost control. Simultaneously, a structured driver safety program protects your most valuable assets, your people, while reducing liability and insurance premiums. These elements work in concert, creating a cycle of continuous improvement where every piece of data informs better decision-making.

From Strategy to Action: Your Next Steps

Adopting these principles is not an overnight process but a phased implementation. To begin your transformation, focus on these key takeaways:

- Start with Data: Your first step should be to implement or upgrade your fleet management software. Without accurate data from telematics and analytics, optimizing routes, monitoring driver behavior, and managing vehicle lifecycles becomes guesswork.

- Prioritize Proactive Maintenance: Move away from a "fix it when it breaks" mentality. A well-documented preventive maintenance program is one of the most effective ways to reduce unexpected downtime, control long-term repair costs, and extend the life of your vehicles.

- Empower Your Drivers: Your drivers are at the forefront of your operations. Investing in their training and creating a strong safety culture not only ensures compliance but also improves morale, reduces accidents, and enhances your brand's reputation with every customer interaction.

Ultimately, mastering these fleet management best practices transforms your fleet from a cost center into a strategic advantage. It allows you to deliver superior service, reduce your environmental footprint, and build a more resilient, future-proof operation. Many of these principles of efficiency and data utilization are universal across business operations. To gain a broader perspective on operational excellence, consider these valuable insights on the 7 Field Service Management Best Practices for 2025, which often overlap with fleet optimization. By integrating these high-level strategies, you create a powerful synergy that propels your entire organization forward.

Ready to pair industry-leading best practices with world-class electric vehicles? Discover how the advanced engineering and superior performance of Solana EV can elevate your fleet's efficiency and sustainability. Visit Solana EV to explore our lineup and build a fleet that's truly built for the future.