Electric vehicle parts suppliers are the companies designing, building, and delivering the high-tech heart of an EV—everything from the battery packs and electric motors to the power electronics and thermal management systems that keep it all running smoothly. The global shift toward electric mobility is completely redrawing the map of the automotive industry, and a new, more complex supply chain is emerging right along with it.

The New Automotive Landscape of EV Part Suppliers

The world of electric vehicle parts suppliers is a completely different beast compared to the supply chain that supported traditional gas-powered cars for over a century. It's like the difference between building a cutting-edge gaming PC and assembling a classic mechanical watch. Both demand precision, but the core components, the expertise needed, and the manufacturing process itself are fundamentally separate.

The EV supply chain is built on a foundation of advanced electronics, sophisticated software, and complex battery chemistry—not pistons, crankshafts, and fuel injectors. This seismic shift has thrown the doors wide open for a new generation of suppliers while forcing established names to adapt or risk being left behind. It's no longer just about metal-bashing and mechanics; it's about managing high-voltage systems, intricate software integration, and sourcing critical raw materials like lithium and cobalt.

This new complexity demands a fresh set of skills. For technicians and dealerships to stay relevant, getting a solid grip on these systems isn't just a good idea—it's essential. You can learn more about this in our guide to electric vehicle training programs.

Key Differences Between EV and ICE Vehicle Supply Chains

To truly grasp how much has changed, it helps to see a direct comparison. The following table breaks down the fundamental distinctions between the supply chains for electric and internal combustion engine vehicles.

| Attribute | Electric Vehicle (EV) Supply Chain | Internal Combustion Engine (ICE) Supply Chain |

|---|---|---|

| Core Components | Battery packs, electric motors, inverters, on-board chargers, power electronics. | Engines, transmissions, fuel systems, exhaust systems, pistons. |

| Supplier Expertise | Focus on battery chemistry, software development, high-voltage electronics, thermal management. | Expertise in mechanical engineering, metallurgy, precision machining, fluid dynamics. |

| Manufacturing Focus | Advanced battery cell and pack assembly, intricate electronics integration, software flashing. | Casting, forging, and machining of metal parts; assembly of complex mechanical systems. |

As you can see, the divergence is stark. The two ecosystems rely on entirely different technologies and skill sets, which is why the transition has been so disruptive for legacy automakers and suppliers alike.

Explosive Growth and Market Dynamics

The appetite for EV components is growing at a staggering pace. A recent market research report valued the electric vehicle parts and components market at USD 205.82 billion. That same report projects it will rocket to an estimated USD 1.57 trillion by 2034, which is a massive compound annual growth rate (CAGR) of 22.5%.

This explosive growth is fueled by more than just vehicle sales; it's also driven by the rapid expansion of charging infrastructure and the demand for fast-charging solutions, all of which require their own specialized components.

The transition to electric vehicles isn't just a change in powertrain; it's a complete reimagining of the automotive supply ecosystem. Success now depends on agility, innovation in battery technology, and deep software expertise.

To get the full picture, you have to look at the broader e-mobility landscape that supports the EV sector. This includes everything from charging network development to breakthroughs in renewable energy, and all of these factors directly influence the parts suppliers.

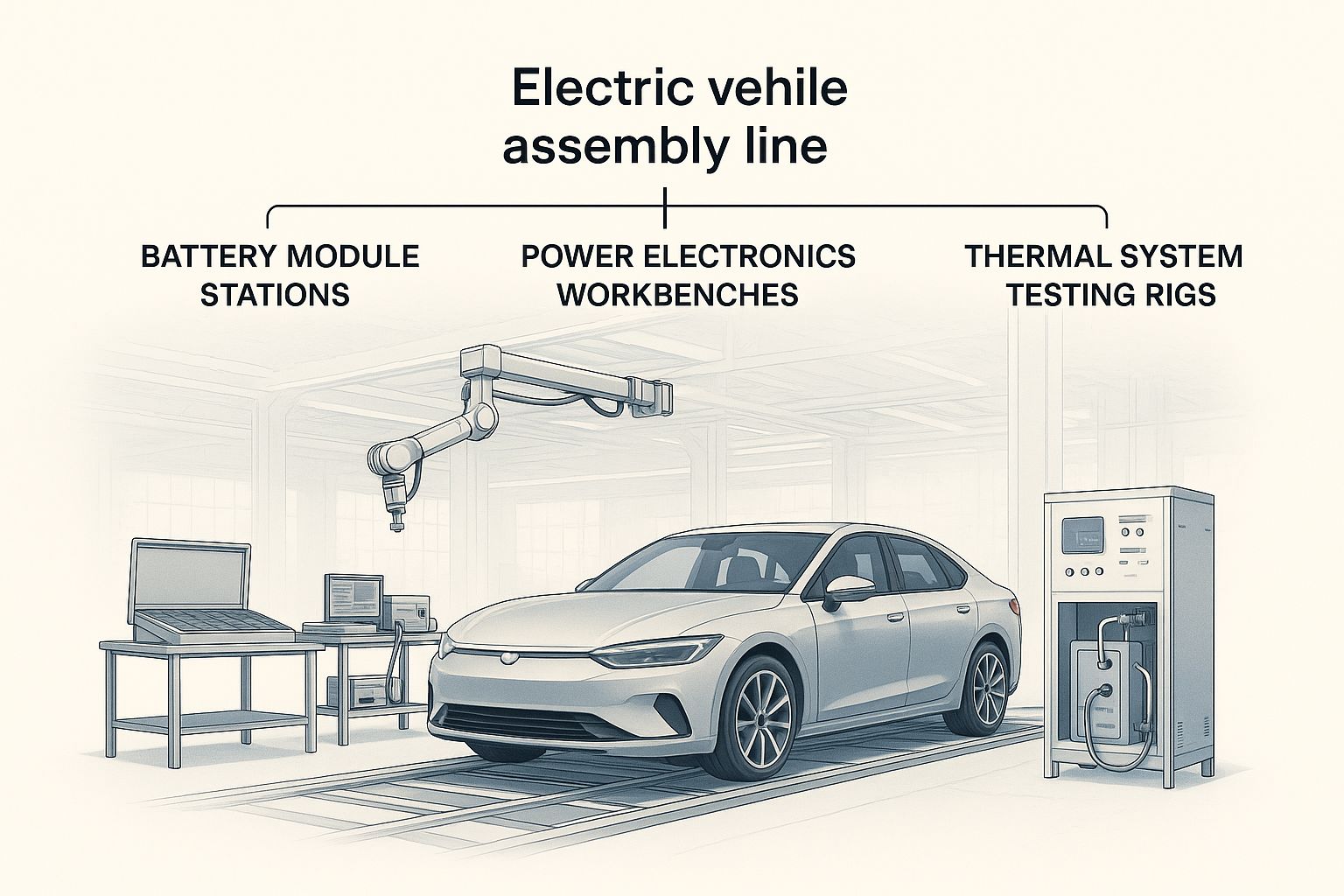

The infographic below gives a great visual of the modern EV assembly process, highlighting the specialized stations for battery modules, power electronics, and thermal systems.

This really brings to life how an EV's core systems come together, and it underscores just how specialized each stage of manufacturing has become.

Understanding the Different Types of EV Suppliers

Getting your head around the world of electric vehicle parts suppliers means figuring out who the key players are and what they actually do. It's not a one-size-fits-all situation; different suppliers operate at different levels of the manufacturing chain and focus on completely separate markets.

Think of it like building a house. You've got the general contractor—the big name on the sign out front—who oversees the whole project. But they aren't mixing the concrete or wiring the outlets themselves. For that, they rely on specialized subcontractors for plumbing, electrical, and framing. The EV world works in a very similar, layered way.

At the very top, you have the automakers everyone knows, like Ford or General Motors. We call them Original Equipment Manufacturers (OEMs). They're the ones designing and assembling the final car, but they don't make every single piece. Instead, they pull in major systems and components from a whole network of trusted partners.

The Tiered Supplier System

The automotive supply chain isn't a chaotic free-for-all; it's a highly organized ecosystem. Knowing this hierarchy makes it much clearer who makes what and who they're making it for.

-

Tier 1 Suppliers: These are the general contractors of the auto industry. They work hand-in-glove with the OEMs to engineer and build entire vehicle systems. We're talking about companies that deliver a complete battery pack, a fully assembled electric axle, or the whole infotainment system you interact with. They're deeply involved from the very early stages of a new vehicle's design.

-

Tier 2 Suppliers: Think of these guys as the specialized subcontractors. They supply crucial components to the Tier 1 suppliers, not directly to the automaker. For example, a Tier 2 company might be an expert at manufacturing individual battery cells, which a Tier 1 supplier then assembles into the finished battery pack.

-

Tier 3 Suppliers: This is the foundational level. Tier 3 suppliers provide the raw materials and basic building blocks. They're the ones supplying processed metals, molded plastics, and simple electronic components to the Tier 2 manufacturers. Their work is absolutely essential—it's the very start of the chain.

This tiered system is all about specialization and efficiency. It allows each company to get really, really good at what it does. A typical EV you see on the road today has parts from hundreds of different suppliers across all these tiers.

OEM vs. Aftermarket Suppliers

Beyond this manufacturing pyramid, there's another important way to classify suppliers: by the market they sell to. This distinction is critical, whether you're a dealership service center or just a car owner trying to find the right replacement part.

Original Equipment (OE) Suppliers are the companies that provide parts directly to automakers for building new cars. These are the factory-spec components that get installed on the assembly line. When you buy an "OEM part" from a dealer for a repair, you're getting a component made by the very same company that built it for the factory in the first place.

An OE part is essentially the identical twin to the one your vehicle had when it first rolled off the assembly line. That means you can count on a perfect fit, flawless function, and zero compatibility issues.

On the other hand, Aftermarket Suppliers make parts for the world of repair, replacement, and customization after a vehicle has already been sold. The quality here can be all over the map. You'll find parts that meet or even exceed the original factory standards, but you'll also find much cheaper alternatives. The aftermarket is where you get everything from a basic set of replacement brake pads to high-performance suspension kits, catering to the long-term needs of keeping cars on the road and letting owners personalize them.

Core EV Components and Their Specialized Suppliers

Before you can really get a handle on the world of electric vehicle parts suppliers, you need to understand what makes an EV go. It's a completely different beast from a gas car. Instead of thousands of moving mechanical parts, an EV’s soul lies in just a few key, high-tech systems.

Think about the difference between a classic mechanical watch and a modern smartwatch. The EV is a lot like the smartwatch—its identity is defined by its battery, its motor, and the electronic "brain" that orchestrates everything. These aren't just off-the-shelf parts; they come from distinct technological arenas, each with its own circle of expert suppliers.

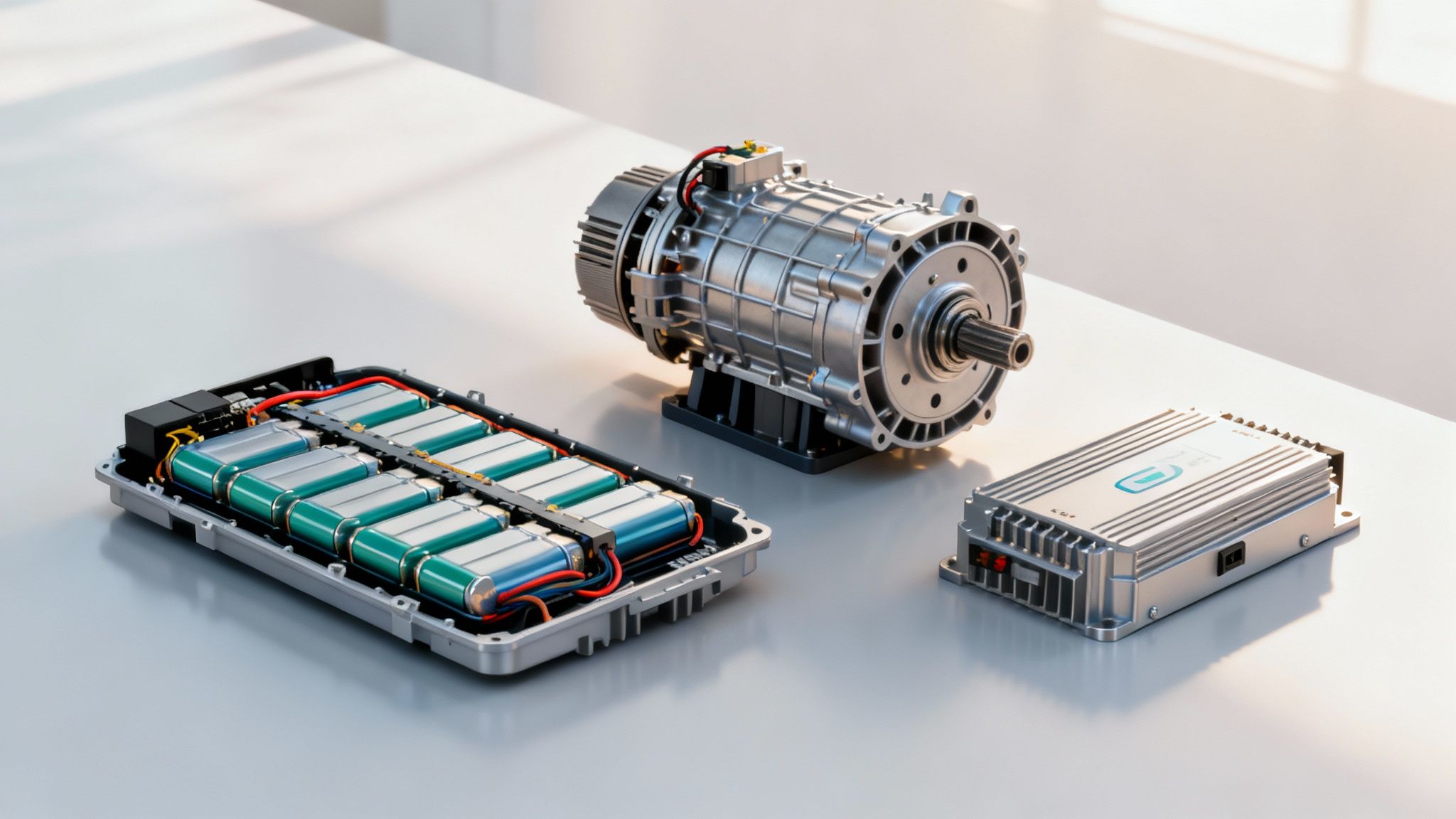

The Heart of the EV: The Battery Pack

Make no mistake: the battery is the single most important—and expensive—component in any electric vehicle. It's the gatekeeper of range, performance, and how quickly you can charge. An EV battery isn't one solid block, either. It’s a sophisticated system built from hundreds, sometimes thousands, of individual lithium-ion cells. These cells are grouped into modules, which are then assembled into the final pack.

Suppliers in this space are true masters of electrochemistry and thermal management. They aren’t just selling batteries; they’re delivering complete energy storage solutions. A modern EV battery pack is an ecosystem that includes:

- Battery Management System (BMS): This is the pack’s onboard computer, constantly monitoring the health, temperature, and charge of every cell to keep things safe and extend the battery's life.

- Thermal Management: These are the advanced liquid- or air-cooling systems that prevent overheating during hard driving or fast charging, keeping everything at its optimal temperature.

- Structural Casing: This is the tough, protective shell that shields the delicate cells from the elements and physical impacts. It's often designed to be part of the vehicle's frame itself.

Companies like CATL, LG Energy Solution, and Panasonic are the heavy hitters here. While the tech is evolving at a breakneck pace, the fundamentals remain the same. To see these concepts at play on a smaller scale, it’s worth checking out our guide on the best lithium batteries for golf carts.

The Muscle: Electric Motors

If the battery is the heart, then the electric motor is the muscle. Its job is to turn electrical energy from the battery into the raw mechanical force that spins the wheels. Unlike the combustion engines we're used to, EV motors are incredibly efficient, surprisingly compact, and deliver that signature instant torque for an exhilarating rush of acceleration.

Suppliers specializing in motors focus on different technologies, like permanent magnet synchronous motors (PMSM) or AC induction motors. They often deliver entire drive units—a slick, integrated package containing the motor, gearbox, and power electronics all in one.

The Brain: Power Electronics

The power electronics are the unsung heroes of every EV. This group of components includes the inverter, which cleverly converts the battery's DC power into the AC power the motor needs to run. It also includes the on-board charger (OBC), which manages the flow of electricity from a charging station into the battery.

Think of these components as the EV's central nervous system, directing high-voltage power with incredible precision and efficiency.

As carmakers increasingly adopt higher-voltage 800V architectures to slash charging times, the need for more advanced, capable inverters and chargers is exploding. This massive technological jump is forcing suppliers to innovate faster than ever.

This shift toward 800V systems is a huge deal. While falling Li-ion battery prices are already contributing about a +1.2% impact to the market's global growth forecast, the move to 800V tech adds another +0.8%. In this dynamic environment, many automakers are bringing battery pack assembly in-house. This pressures top-tier suppliers to offer more value, bundling their hardware with advanced software and integrated thermal solutions to stay competitive.

How to Choose the Right EV Parts Supplier

Picking the right electric vehicle parts supplier is one of the most important calls you'll make for your business. It’s so much more than just hunting for the cheapest quote. You're essentially choosing a long-term partner whose work will directly reflect on you.

Think of it this way: their reliability, the quality of their components, and their expertise are all baked into your final product and your company's reputation. A low price tag is worthless if the parts fail, show up weeks late, or don't meet critical safety standards. A strong, dependable supply chain is built on trust and proven performance, not just bargain hunting.

Evaluating Technical Expertise and Quality

First things first, you need to look past the glossy brochures and really dig into a supplier's technical chops. For EVs, that means having a serious command of high-voltage electronics, battery chemistry, and complex software integration.

Don't hesitate to get granular. Ask them about their R&D process, their specific testing protocols, and the real-world experience of their engineering team.

A truly professional supplier will have no problem providing detailed documentation and performance data for every component. One of the most critical credentials you should look for is the IATF 16949 certification. This is the global gold standard for quality management in the automotive world. Seeing it tells you the supplier is committed to rigorous processes for quality control, safety, and constant improvement.

Selecting a supplier without IATF 16949 certification is a significant risk. This standard ensures that every part is manufactured under rigorous, repeatable processes designed to prevent defects and ensure vehicle safety.

Another thing to consider is cybersecurity. As vehicles get smarter and more connected, the software running critical parts like the battery management system (BMS) can become a target. A supplier who's ahead of the curve will have solid cybersecurity measures in place to protect their electronics from threats.

Assessing Reliability and Scalability

A supplier who looks amazing on paper is no good if they can't actually get you the parts you need, when you need them. You have to gauge their real-world reliability.

Ask them tough questions about their supply chain. How do they manage inventory? What are their typical lead times? More importantly, what's their backup plan for when things go wrong? A well-prepared supplier will have a ready answer for what happens when a raw material suddenly becomes scarce or a major shipping route gets disrupted.

You also need to think about your own growth. Can this supplier scale with you? If your order volume suddenly doubles, will their quality or delivery times suffer? This is absolutely essential for any growing business. You need a partner who can grow right alongside you.

Finally, get a firm handle on their warranty and support. A strong warranty isn't just a piece of paper; it’s a sign that the supplier stands behind their product's quality. Understanding the fine print can save you a world of trouble later. Our guide to understanding an electric vehicle warranty breaks down exactly what you should be looking for.

Navigating the Growing EV Aftermarket

The EV aftermarket is where the real action is happening for independent shops, dealerships, and even savvy DIYers. This is the world of repairs, maintenance, and upgrades that kicks in after a car leaves the factory floor. It’s a completely different ballgame from the OEM (Original Equipment Manufacturer) world, which is all about feeding parts to the assembly line.

I like to think of it this way: the OEM supplier is like a new home builder, working on a huge scale with predictable, bulk orders. The aftermarket supplier, on the other hand, is the specialized renovation contractor. They’re the ones you call for unique projects on existing homes, focusing on compatibility, custom fixes, and specific problems. These electric vehicle parts suppliers are the expert renovators for the cars we already drive.

And this market is absolutely exploding. The first big waves of EVs are now coming off their factory warranties, and owners are looking for cost-effective ways to keep them running. We're moving beyond simple tire changes and into complex component repairs, which is opening up a whole new world for suppliers who can crack that code.

Where the Real Opportunities Are

The needs of the EV aftermarket are far more complex than just replacing brake pads or windshield wipers. The biggest growth is happening in highly technical, high-value areas that demand serious expertise.

Three segments are leading the charge:

- Replacement Battery Packs: Finding a new battery pack used to be a dealership-only nightmare. Now, specialized suppliers are offering refurbished, remanufactured, and sometimes even upgraded battery solutions. They’re providing a crucial, often more affordable, alternative to brand-new OEM packs.

- Electronic Control Modules: When a critical electronic module goes down, you can't just grab one off the shelf. Aftermarket specialists are filling this gap by supplying tested, reliable modules that play nice with the vehicle’s existing software, which is no small feat.

- Charging Equipment and Accessories: This is a massive and fast-growing category. It covers everything from home wall chargers and public charging stations to the portable chargers and adapter cables every EV owner needs. More EVs on the road means a greater need for a solid charging ecosystem to support them.

The thing to remember about EVs is that the aftermarket isn't just about swapping parts. Because of the complexity of battery systems and power electronics, it’s about offering a complete solution—one that often includes diagnostics, software flashing, and ongoing technical support.

Global Trends and Regional Hotspots

The EV aftermarket isn't one-size-fits-all. It’s a patchwork of markets shaped by local regulations, what consumers want, and the charging infrastructure that’s available. A hot-ticket item in one country might barely register in another.

Take India, for example. Government initiatives and booming cities are creating a huge demand for aftermarket EV products, especially charging stations and clever battery-swapping systems. Meanwhile, Europe's market is maturing fast. Countries like Germany and France are leading the way, pushed forward by strong government support for clean energy. In Germany, a mix of incentives and a powerful automotive industry has created a massive need for top-tier aftermarket parts and expert repair services.

To really get a handle on how these different markets are evolving, you can find more detail on global EV aftermarket trends. Understanding this global picture is essential for anyone looking to source or sell parts across borders.

Got Questions? We’ve Got Answers.

Jumping into the world of electric vehicle parts suppliers can feel like learning a whole new language, especially when you're used to the traditional auto industry. To help cut through the noise, we've put together some straight answers to the questions we hear most often.

Think of this as your quick guide to making smarter decisions, whether you're running a repair shop, managing a dealership, or looking after an entire supply chain.

How Is Sourcing EV Parts Different from Sourcing for Gas Cars?

The biggest shift is moving from mechanics to electronics. With a traditional car, you're chasing down mechanical parts—engines, transmissions, exhaust systems. For an EV, you're suddenly in the world of high-tech electronics: battery cells, electric motors, and complex power control units. It's a whole different ballgame.

This means you need partners who live and breathe electrical engineering, software, and advanced battery chemistry. Plus, EV technology is changing at lightning speed. Unlike the standardized world of internal combustion engines, ensuring parts are compatible and won't be obsolete tomorrow is a much bigger headache.

A typical gas-powered car is a puzzle of about 30,000 parts, most of them mechanical. An EV has far fewer pieces, but its heart—the battery, motor, and electronics—is infinitely more complex. This completely changes what you need to look for in a supplier.

How Can I Actually Check if an EV Parts Supplier Is Any Good?

You have to look past the fancy website and glossy brochures. Vetting a supplier means rolling up your sleeves and digging into their real-world processes and credentials to make sure they can handle the intense demands of the auto industry.

Here’s what you absolutely need to check:

- Look for Certifications: The gold standard is IATF 16949. If a supplier has this, it means they're serious about quality, preventing defects, and getting better over time. It’s a non-negotiable for the automotive world.

- Ask for the Data: A good supplier won't hesitate to share detailed performance specs, testing results, and technical documents. If they get cagey or give you vague answers, that's a huge red flag.

- Check Their Track Record: Don't be shy. Ask for case studies or references from other automakers or major suppliers they've worked with. A history of successful partnerships is one of the best signs of a reliable company.

- See How They Handle Support: What's their warranty policy? How transparent is their supply chain? Will they be there to help if something goes wrong? A supplier who stands behind their product is a partner you can trust.

Are Aftermarket EV Parts as Good as the Originals from the Factory?

Honestly, it depends. The quality of aftermarket EV parts is all over the map, so you have to choose wisely. There are fantastic aftermarket companies making parts that are just as good—and sometimes even better—than the OEM (Original Equipment Manufacturer) versions. They can be a great way to save money on repairs or get performance upgrades.

But there's a flip side. The market is also flooded with cheap knock-offs that haven't been properly tested, use shoddy materials, or ignore critical safety standards. Putting one of these parts in a vehicle isn't just a risk to performance; it's a serious safety hazard.

When you're looking at aftermarket electric vehicle parts suppliers, stick with companies that have a solid reputation and are transparent about how they make their products. And when it comes to the really critical stuff, like the battery pack or high-voltage electronics, playing it safe with OEM or a top-tier certified aftermarket supplier is always the smartest move.

At Solana EV, we get that quality, performance, and reliability are everything. Our premium, street-legal electric vehicles are built from the ground up with best-in-class components to deliver a ride that’s second to none. Whether you’re a dealership ready to expand your inventory or a driver looking for the best personal EV out there, we’ve got your back.

See our full lineup and explore our dealer partnership programs by visiting us at SolanaEV.com.