The electric vehicle battery technology we see in cars today is the single biggest piece of the puzzle. It dictates performance, range, and ultimately, the price tag. At its heart, an EV battery is all about storing electrical energy through chemical reactions and then releasing it on demand. It's both the fuel tank and the engine, all rolled into one. Getting your head around this technology is the key to understanding the massive shift away from the gas pump.

The Power Behind the Electric Revolution

The battery is the heart of any modern electric vehicle. It’s a highly sophisticated energy storage system that controls just about every part of the driving experience, from how far you can go on a single charge to how quickly the car launches off the line. It's not like the AA battery in your TV remote; think of it as a far more advanced, rechargeable power source.

This guide will demystify the world of electric vehicle battery tech. We’ll look at what makes one battery different from another, giving you the confidence to understand the specs that actually matter when you're looking at an EV. The goal is to give you a clear roadmap, starting with the basics and moving all the way to what's next for EV power.

What This Guide Covers

This journey into the core of EVs will give you a practical understanding of this all-important component. We'll be digging into the critical elements that make up the battery ecosystem:

- Core Chemistries: We'll explore the different chemical makeups, like the various kinds of Lithium-ion, and break down why they've become the industry standard.

- Key Performance Metrics: You'll learn what terms like energy density and cycle life really mean for your daily drive.

- Design and Structure: We'll see how thousands of tiny cells are ingeniously packaged together to create the massive, powerful battery packs that sit under the car floor.

- Future Innovations: We'll take a peek at the next generation of power, from game-changing solid-state batteries to new ideas for sustainable recycling.

Of course, the technology doesn't stop at the car. To really embrace the electric revolution, you have to understand the charging infrastructure that supports it. For a deeper dive, check out this comprehensive guide to EV charger installation to see how this technology extends right into your garage.

At its heart, an EV battery doesn't just store power; it unlocks potential. It redefines mobility by turning silent, clean electricity into motion, making it the central pillar of the automotive industry's future.

The Long Road to Modern EV Batteries

It might seem like electric cars are a recent invention, but they've been around for a surprisingly long time. To really get a feel for today's battery tech, it helps to rewind the clock a bit. Believe it or not, at the turn of the 20th century, electric cars were actually quite popular, gliding silently down city streets well before the roar of gasoline engines took over.

Back then, the best tech available was the lead-acid battery. And for a moment, it looked like the future. By 1900, electric models made up an incredible 38% of all cars built in the United States. But that early lead didn't last. If you're curious about this forgotten chapter of automotive history, S&P Global has a great piece on EV battery evolution.

The biggest roadblock was the battery itself. Lead-acid batteries had a very low energy density—basically, they couldn't store much power for their weight. This meant the cars were incredibly heavy, their range was frustratingly short, and charging them was a slow, painful process.

The Combustion Engine Takes Over

Just as the limits of battery power were becoming clear, Henry Ford was busy perfecting the mass-produced, gasoline-powered Model T. Suddenly, gas stations started popping up everywhere, offering a quick and easy "refill" that electric cars just couldn't compete with.

The internal combustion engine gave drivers the freedom of long-range travel and fast refueling, pushing electric cars to the sidelines for decades. Battery research didn't stop, of course, but it shifted its focus to other things. The dream of a practical electric car went dormant, waiting for a better power source.

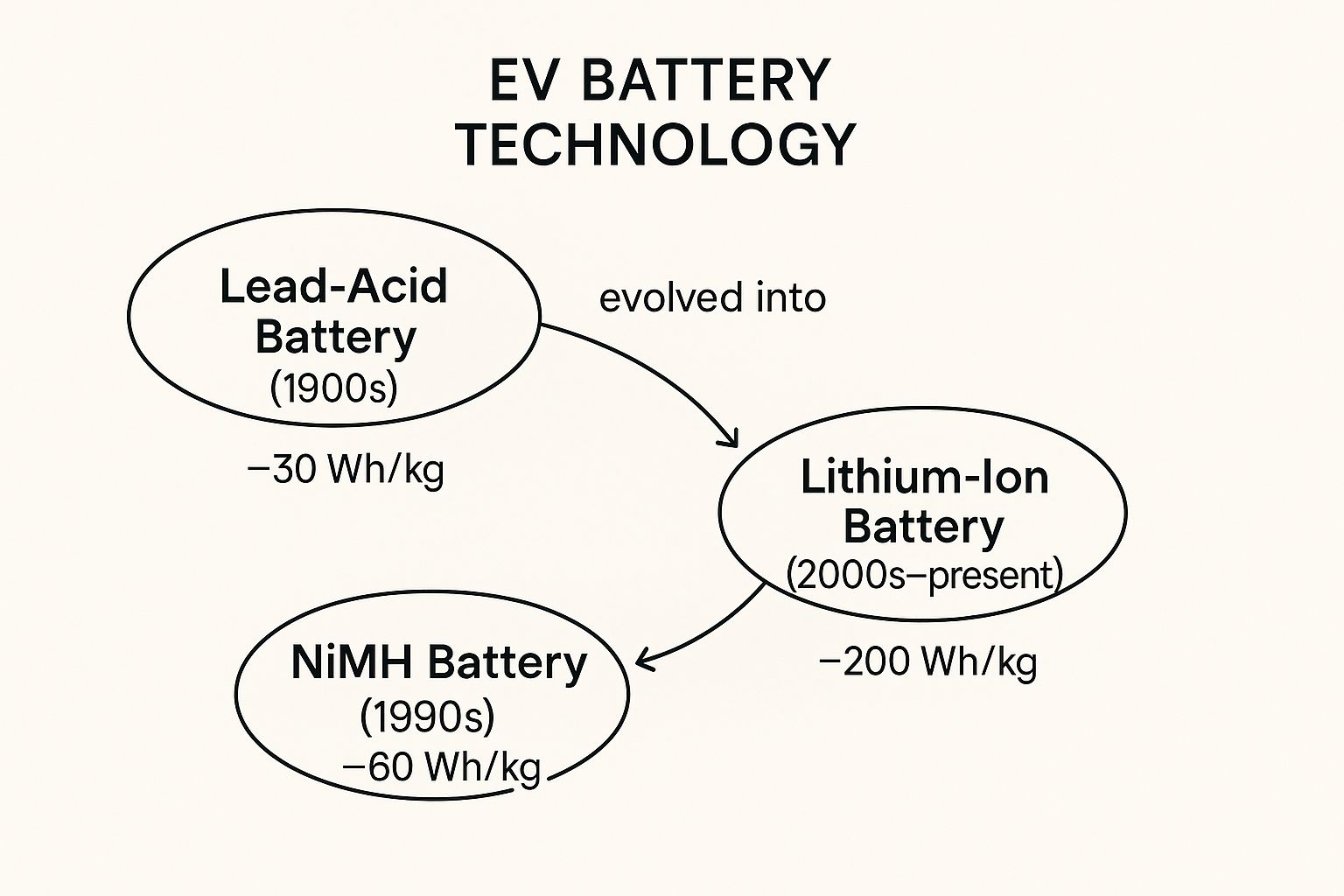

This infographic really puts the leap in energy density into perspective.

You can see how each new type of battery chemistry brought a major boost in performance, setting the stage for the EVs we have today.

Key Breakthroughs in Battery Tech

The electric car’s comeback story started not on the road, but quietly in research labs. A series of crucial discoveries over many years slowly chipped away at the problems that plagued those early EVs.

Here are a few of the biggest steps forward:

- Nickel-Metal Hydride (NiMH) Batteries: These became common in the 1990s and were a huge step up from lead-acid. They powered the first wave of successful hybrid cars, getting drivers comfortable with the idea of an electric motor again.

- The Lithium-Ion Revolution: This was the real turning point. First developed for laptops and phones, lithium-ion (Li-ion) batteries were lightweight and could store a ton of energy. It was a perfect match for cars.

The journey from the heavy, short-ranged lead-acid batteries of the 1900s to today's powerful lithium-ion packs is a story of relentless innovation. It shows how solving tough scientific problems was the key to making modern EVs a reality.

All that steady, patient progress in electric vehicle battery technology is what led us here. The powerful, long-range, and quick-charging cars on the road today are standing on the shoulders of over a century of invention, finally making a hundred-year-old idea a practical choice for everyone.

Understanding How EV Batteries Work

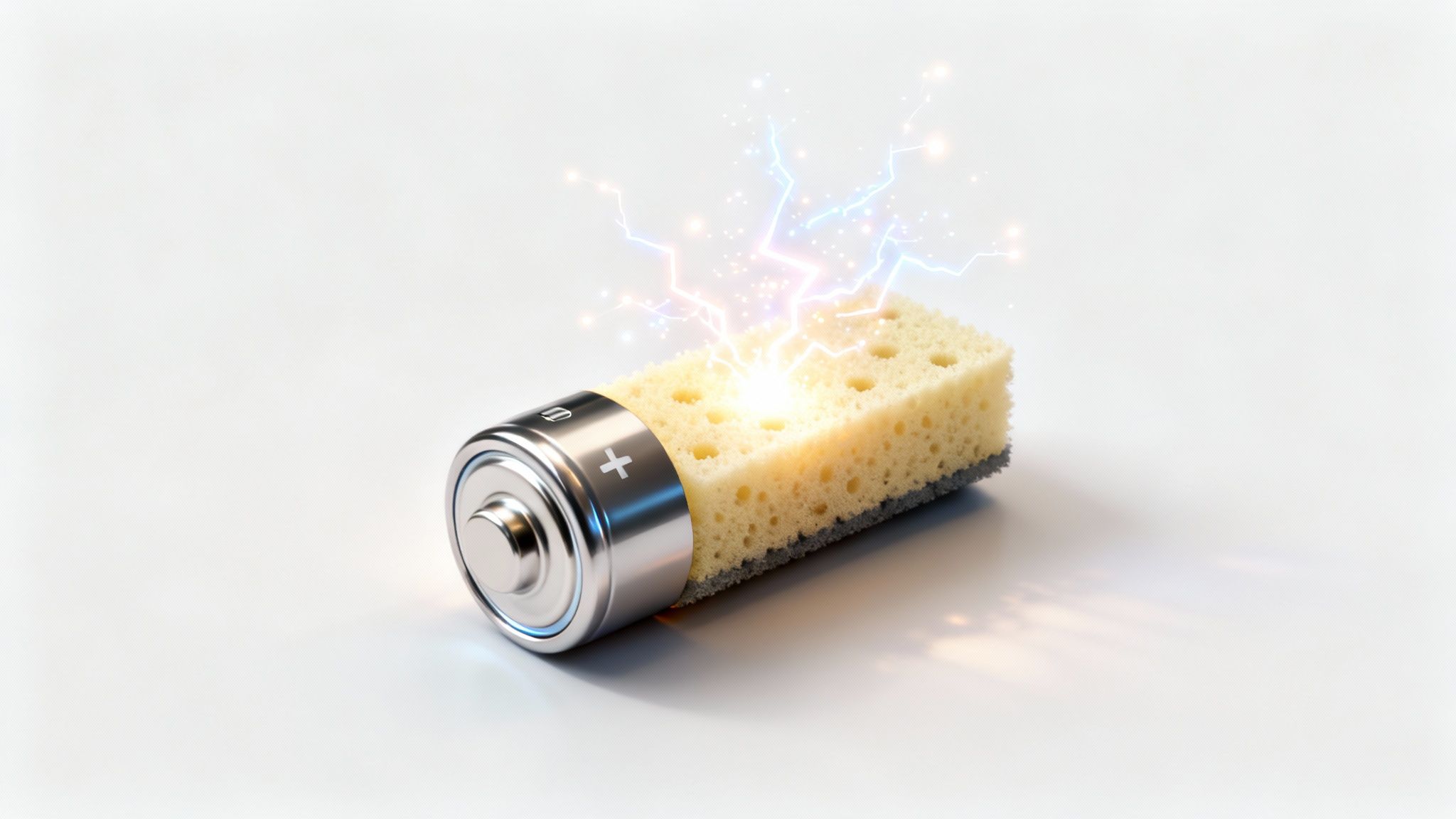

At its heart, an electric vehicle battery does a simple job: it stores energy and releases it on command. A great way to think about it is like a high-tech, rechargeable sponge. When you plug in your EV, you're soaking that sponge with electrical energy, which gets locked away as chemical potential. The moment you press the accelerator, the battery "squeezes" that energy back out as electricity, sending power to the motor and getting you on your way.

This whole dance is choreographed by the movement of tiny charged particles called lithium ions. These ions are the real workhorses, shuttling back and forth between two electrodes—the anode and the cathode—through a special liquid called an electrolyte. It’s this constant, controlled river of ions that creates the electric current turning your wheels.

The vast majority of today's EVs run on lithium-ion (Li-ion) batteries. This isn't by accident. This powerful family of electric vehicle battery technology gives automakers the best all-around package of energy storage, weight, and cost available right now. But here's the catch: not all Li-ion batteries are made the same. Automakers are very particular, choosing specific chemistries to give their vehicles unique personalities.

The Key Players In Battery Chemistry

Think of the "lithium-ion" family as having several branches, each with a unique chemical recipe, or "chemistry." Every recipe brings something different to the table, creating a unique balance of power, longevity, cost, and safety. This is why a lightning-fast performance EV often has a fundamentally different battery than an affordable, everyday commuter car.

Here are two of the most common chemistries you'll find under the floor of a modern EV:

- NMC (Nickel Manganese Cobalt): If you hear a car company bragging about huge range figures, there's a good chance an NMC battery is involved. This chemistry is famous for its high energy density, which is a fancy way of saying it crams a ton of power into a small, lightweight package. It's the go-to choice for long-range and performance EVs where every last mile counts.

- LFP (Lithium Iron Phosphate): LFP batteries play a different game. They might not have the show-stopping energy density of NMC, but their strengths lie elsewhere. They are incredibly durable, famously stable, and safer. Plus, you can often charge them to 100% day in and day out without worrying about premature wear—a huge plus for daily driving.

Picking a battery chemistry is one of the most important decisions an automaker makes. It's a strategic balancing act, weighing the public's thirst for maximum range against the practical realities of cost, safety, and a long service life.

This choice defines the car's purpose. A luxury sedan aiming for 400 miles on a charge will almost certainly use an energy-dense chemistry like NMC. In contrast, an entry-level city car will lean on LFP to keep the sticker price down while promising years of reliable service. These same trade-offs matter in other applications, too; for instance, choosing the right lithium battery for a golf cart often means prioritizing the safety and incredible lifespan offered by LFP.

A Tale Of Two Chemistries: NMC vs. LFP

To really see these trade-offs in the real world, let's compare NMC and LFP head-to-head. Picture two EVs with identically sized battery packs. The one with the NMC battery will boast a longer official range because its "sponge" can simply hold more energy for its size. However, the EV with the LFP battery will likely be more affordable and its battery pack could easily outlast the NMC pack over years of charging cycles.

This table gives a clear, side-by-side look at the different chemistries you'll find in showrooms today.

Comparing Common EV Battery Chemistries

| Chemistry Type | Primary Advantage | Key Limitation | Typical Use Case |

|---|---|---|---|

| NMC | High Energy Density (Longer Range) | Higher Cost, Relies on Cobalt | Performance and Long-Range EVs |

| LFP | Long Cycle Life, High Safety, Lower Cost | Lower Energy Density (Shorter Range for same weight) | Standard-Range EVs, Commercial Vehicles |

| NCA | High Power Output | Shorter Lifespan, Higher Cost | High-Performance Luxury EVs |

This practical difference is exactly why a company like Tesla uses LFP batteries for its standard-range models but switches to NMC or NCA (Nickel Cobalt Aluminum Oxide) for its long-range and performance versions. It's a brilliant strategy. It allows them to hit a lower price point for everyday drivers while still offering the extreme range and acceleration that enthusiasts crave. This smart use of electric vehicle battery technology is a huge part of what's making EVs a viable option for more and more people.

The Metrics That Define Battery Performance

When you're looking at different EVs, it's easy to get buried in a mountain of technical jargon. What really makes one battery better than another? It all boils down to a few key performance metrics that control everything from how far you can drive to how long you’ll spend at a charging station.

Getting a handle on these numbers is like learning the language of electric vehicle battery technology. Instead of just looking at a car's advertised range, you can start to understand the why behind it. Let's unpack the most important specs in simple, real-world terms.

Energy Density: The Size of Your Fuel Tank

If there's one metric everyone talks about, it's energy density. Measured in watt-hours per kilogram (Wh/kg), this number tells you how much juice a battery can store for a given weight. Think of it as the size of your EV’s fuel tank. Higher energy density means you can cram more range into a battery pack that's smaller and lighter.

This is a game-changer for car designers. A lighter battery makes a car more efficient, improves its handling, and boosts overall performance. It's why chemistries like NMC are the go-to for long-range models, allowing them to break the 400+ mile barrier on a single charge without feeling weighed down.

A battery's energy density directly translates to driving freedom. It's the difference between a car built for city commuting and one designed to confidently tackle a cross-country road trip.

Power Density: How Fast You Can Accelerate

Energy density is about how much fuel you're carrying, but power density is about how fast you can burn it. Measured in watts per kilogram (W/kg), this metric defines how quickly a battery can unleash its stored energy. For the driver, this means one thing: acceleration.

Ever felt that instant, pin-you-to-your-seat takeoff in an EV? That’s high power density at work. It's the electric equivalent of horsepower, allowing the battery to send a massive surge of current to the motors whenever you stomp on the pedal. This is the secret behind the mind-bending 0-to-60 times that performance EVs are famous for. It also plays a part in how quickly a battery can accept a charge.

C-Rate and Charging Speed

The C-rate is a simple way of talking about charging and discharging speed relative to a battery's total capacity. A 1C rate means a battery can theoretically go from empty to full in one hour. A 2C rate cuts that time to 30 minutes, while a 0.5C rate would take two hours.

This little number is at the heart of the charging experience. The entire industry is in a race to achieve higher C-rates to slash the time we spend plugged in. The ability to add 100 miles of range in just 10 minutes is a direct result of battery tech that can handle these higher C-rates without overheating or degrading.

This push for faster charging is a critical piece of the EV adoption puzzle. You can learn more about how this technology fits into the broader network of electric vehicle charging infrastructure.

Cycle Life: How Long Your Battery Lasts

Finally, there’s cycle life. This tells you how many full charge-discharge cycles a battery can go through before its capacity starts to fade noticeably. One cycle is defined as charging from 0% to 100% and then draining it all the way back down. This metric is the best indicator of a battery’s long-term health and durability.

A modern EV battery is built to last. Most are designed for thousands of cycles, which is why automakers confidently offer warranties of 8 to 10 years or 100,000 miles. For perspective, a battery with a 2,000-cycle life and a 250-mile range could theoretically power a car for 500,000 miles before its capacity drops below the typical warranty threshold of 70-80%.

This incredible longevity is what makes an EV a solid long-term investment. Unlike a complex gasoline engine, a well-maintained battery pack is designed to power a vehicle for its entire useful life.

The Future of Electric Vehicle Battery Technology

The world of electric vehicle batteries is moving at an incredible speed. The lithium-ion batteries powering today's EVs are already impressive, but what's coming next is set to completely redefine the driving experience. We're talking about advancements focused on making EVs safer, giving them more range, and cutting down charging times to a fraction of what they are now.

At the very front of this pack is the solid-state battery. To understand why it's such a big deal, think of the liquid electrolyte in a current EV battery as a little swimming pool that ions have to cross. Solid-state technology gets rid of that liquid "pool" and replaces it with an ultra-thin, solid material, like a slice of ceramic or a special polymer.

This one change has massive knock-on effects. First, by removing the flammable liquid, solid-state batteries are inherently much safer and far less likely to overheat. Even more exciting, this solid structure unlocks the door to using a pure lithium metal anode, a component that could supercharge energy density by 50% or more.

What does that mean for drivers? A future where EVs can realistically travel 500-700 miles on a single charge. It also means charging could become as quick as a pit stop for gas, adding hundreds of miles of range in less than 15 minutes.

The Quiet Rise of Silicon Anodes

While solid-state batteries are the headline-grabbing future, other major improvements are already happening. One of the most promising is the use of silicon in the battery's anode. For years, anodes have been made from graphite, which works well but is reaching its limit for how many lithium ions it can hold.

Silicon, on the other hand, is a storage champion—it can hold up to 10 times more ions than graphite. The big problem? Silicon swells up and cracks as it charges and discharges, kind of like a balloon that's been inflated and deflated too many times. It just couldn't handle the stress.

The clever workaround has been to create a hybrid, mixing small amounts of silicon into a traditional graphite anode. This gives a nice boost to energy density without the cracking and stability issues. In fact, many high-end EVs on the road today are already using this trick to get more miles out of their packs. The race is now on to see how much more silicon engineers can safely add.

Looking Beyond Lithium-Ion

The quest for a better battery isn't just about tweaking lithium-ion designs. Researchers are also digging into completely different chemistries that could offer their own unique advantages. For example, some early EVs from 1997 to 2012 used sodium nickel chloride, or "Zebra," batteries. They needed to be heated to work and didn't offer much power, but they were safe and could last for a long time.

Explorations into chemistries like nickel-cadmium and lithium vanadium oxide have also taken place over the years. This shows us something important: the future might not be a one-size-fits-all solution. Instead, we might see different battery types being used for different kinds of vehicles and applications.

Building a Sustainable, Circular Economy

With millions of EVs hitting the streets, one question looms large: what happens to all those batteries when they're done? The long-term health of the EV industry hinges on creating a circular economy, where old batteries aren't just waste but a valuable resource to be used again.

This forward-thinking approach has two main paths:

- Second-Life Applications: When an EV battery's capacity eventually fades to about 70-80%, it's no longer ideal for powering a car, but it's perfect for a second career in stationary energy storage. These retired packs can store solar power for a home, back up a business, or even help stabilize the entire electric grid.

- Advanced Recycling: Once a battery is truly at the end of its useful life, modern recycling facilities can step in to recover up to 95% of the valuable materials inside, like lithium, cobalt, and nickel. Those recovered metals can then go right back into making brand-new batteries, which dramatically cuts down on the need for new mining.

As we engineer the next generation of EV batteries, it's absolutely essential to embed sustainable technology practices from start to finish. This isn't just about protecting the environment; it’s about building a more resilient and cost-effective supply chain for everyone.

Of course, the road to these next-gen batteries is still being paved. Solid-state technology will almost certainly show up in expensive luxury EVs first before it becomes affordable enough for the mainstream. But the destination is clear—the EV battery of tomorrow will be safer, more powerful, and more sustainable than anything we have today.

Answering the Big Questions About EV Batteries

As electric vehicles become a more common sight on our roads, it's only natural to have questions—and maybe a little skepticism. It's time to separate fact from fiction and get a clear picture of what it’s really like to own an EV.

Let's dive into some of the most common concerns, from battery lifespan to the truth about fast charging.

How Long Does an EV Battery Really Last?

This is probably the biggest question on everyone's mind. The short answer? An EV battery is built to last the life of the car. It’s not like a phone battery that you expect to replace every few years. Automakers stand behind this with hefty warranties, typically covering 8 years or 100,000 miles.

Now, it’s true that all batteries lose a bit of their capacity over time. This process is called degradation. But in an EV, this happens incredibly slowly thanks to sophisticated management systems. A well-maintained battery can easily hold over 70% of its original capacity after a decade on the road, which is plenty for most people's daily commute. To get a better handle on what's covered, it's worth digging into the details of a typical electric vehicle warranty.

A modern EV battery isn't a disposable component; it's a durable, long-term asset engineered to deliver reliable performance for hundreds of thousands of miles. Proper care simply extends that impressive lifespan even further.

Making your battery last even longer is simple. Small habits, like avoiding charging to 100% every single day (sticking to 80% is a great rule of thumb) and keeping the car out of extreme heat or cold when you can, will go a long way in preserving its health.

Does Fast Charging Damage My EV Battery?

Not in the way you might think. While it’s true that DC fast charging puts more stress on a battery than slower home charging, your car is designed to handle it. Every EV has a brilliant piece of tech called a Battery Management System (BMS), which is basically a bodyguard for your battery.

The BMS is constantly monitoring things like temperature and voltage. If things get too warm, it automatically slows the charging speed down to protect the battery cells from any harm.

Here’s a simple way to think about it:

- Level 2 Charging: This is your everyday workhorse. Perfect for overnight top-ups at home, it’s gentle, easy, and cheap.

- DC Fast Charging: This is your road trip hero. It’s designed for those times when you need to get back on the highway fast.

Using a fast charger for its intended purpose—getting a quick boost on a long journey—is perfectly fine and won’t cause any meaningful damage. If you used one exclusively every day for years, you might see slightly faster degradation, but the BMS is always on guard to prevent any real harm.

What Happens to Old EV Batteries?

This is a great question. Contrary to the myth that they just end up in a landfill, old EV batteries are far too valuable to be thrown away. They actually become a vital part of a circular economy in two main ways.

The first step is repurposing. Once a battery has degraded to about 70% capacity, it might not be ideal for powering a car, but it’s still perfect for a second life as a stationary energy storage unit. These retired battery packs can be used to:

- Store solar power for a home or business.

- Act as a backup power source during blackouts.

- Help utility companies stabilize the electrical grid.

After a battery has served its second life and can no longer hold a useful charge, it moves on to the second pathway: recycling. Modern recycling facilities can recover up to 95% of the critical materials inside, including valuable metals like lithium, cobalt, and nickel. These materials are then funneled right back into the supply chain to create brand-new batteries, which dramatically reduces our reliance on new mining.

At Solana EV, we believe in the power of clear information to drive the future of mobility. Our vehicles are built with durable, high-performance battery technology designed for the long haul. Discover our lineup of premium electric vehicles at https://solanaev.com.