When you're trying to lower operational costs, the first instinct is often to just start cutting things. But that's a reactive, short-term fix. The real win comes from building smarter, more resilient systems before you have to make those tough calls. It’s about being proactive.

This means looking at strategic ways to boost efficiency, like bringing in automation, rethinking how you buy supplies, and even exploring energy-saving moves like switching to an EV fleet.

Moving Beyond Budget Cuts to True Cost Efficiency

Let's be real—slashing budgets might plug a hole for a quarter, but it's not a genuine strategy for long-term financial health. The most forward-thinking businesses have stopped playing defense with their budgets. Instead, they're building a culture of proactive cost efficiency that examines the root causes of expenses, not just the numbers on a spreadsheet.

Think of this guide as your roadmap. We're moving beyond the simple question of "What can we cut?" and asking a much more powerful one: "How can we operate smarter?"

The Mindset Shift to Sustainable Savings

The heart of this strategy is getting your entire team on board with spotting and stamping out waste. When efficiency becomes everyone’s job, not just a task for the finance department, you'll uncover savings you never knew existed.

This modern approach really stands on a few key pillars:

- Strategic Tech Investments: This is about using tools like automation and smart analytics to take the friction out of your workflows. I've seen companies that embrace AI and automation cut their operational costs by as much as 30%. It’s a game-changer.

- Constant Process Refinement: Always be looking at how work gets done. Where are the bottlenecks? What steps are redundant? Smoothing these out saves time and money.

- Empowering Your People: Give your team the training and motivation to find better, more efficient ways to do their daily jobs. They're on the front lines and often see things management misses.

This isn't just about pinching pennies. It’s about creating a more agile and competitive organization. When you focus on efficiency, you free up resources—time, money, and talent—to pour back into the things that actually drive growth and innovation.

For a closer look at getting the most from your current resources and putting smart strategies in place, it’s worth exploring how to improve operational efficiency. That foundation will set us up perfectly for the practical, actionable steps we’ll dive into next, from smarter procurement to optimizing your vehicle fleet.

Slash Repetitive Work with Smart Automation

Manual, repetitive work is the silent killer of productivity. Think about how many hours your team sinks into tasks like data entry, processing invoices, or pulling the same reports week after week. It’s not just a time suck; it's a major source of human error, which always costs more to fix later.

Smart automation isn't about replacing your people. It’s about letting them off the hook from the monotonous work so they can focus on what really matters—critical thinking, creative problem-solving, and strategic planning that actually moves the needle for your business.

Where to Start with Automation

Your best bet for automation is to target tasks that are rule-based, repetitive, and happen in high volumes. A dead giveaway is any process where an employee is just a human bridge between two software systems, copying and pasting data all day.

Finance and HR departments are often overflowing with these kinds of opportunities. Just think about the possibilities:

- Finance: Imagine your accounts payable specialist analyzing spending trends to find cost-saving opportunities instead of manually keying in invoice data.

- HR: What if your HR manager could develop a new training program to boost employee retention instead of drowning in routine onboarding paperwork?

- Operations: Your operations lead could be analyzing demand forecasts to prevent overstocking, rather than manually checking inventory levels every day.

By letting technology handle the grunt work, you’re not just saving time; you're reallocating your team’s brainpower to where it has the most impact.

The Power of AI and RPA

Today's automation tools are much more than simple scripts. Two technologies, in particular, are making a huge difference for businesses looking to trim operational fat: Robotic Process Automation (RPA) and Artificial Intelligence (AI).

RPA uses software "bots" that are trained to mimic human actions on a computer. They can log into apps, move files, fill out forms, and pull data just like a person would, but they do it 24/7 without getting tired or making typos. It’s like having a digital workforce dedicated to your most tedious tasks.

AI adds a layer of intelligence to the mix. AI-driven analytics can dig through massive amounts of data to spot patterns and make predictions. It can forecast customer demand, predict when a machine needs maintenance before it breaks down, or optimize delivery routes for your entire fleet to cut down on fuel and time.

The results speak for themselves. Organizations that embrace AI and automation have been shown to reduce operational costs by as much as 30%. These savings come directly from automating the routine processes that used to eat up so many man-hours. Discover how digital transformation drives cost efficiency.

This isn't just about doing the same old things faster. It's about creating fundamentally smarter, more efficient ways of operating. The capital you free up can then be poured back into growth, innovation, and other strategic initiatives that deliver a far greater return than manual data entry ever could.

Unlock Savings with Strategic Procurement

Think about your company's purchasing process. For many, it's a simple, reactive cycle: a department needs something, so someone finds a supplier and buys it. While this gets the job done, it often leaves a surprising amount of money on the table. A much smarter approach can unlock serious savings without sacrificing quality.

The key is to shift your mindset from simple purchasing to strategic category management. This is an expert-level method where you group similar products or services together and manage them as a single, cohesive unit. Instead of buying laptops from one vendor and software from another whenever the need arises, you start treating all your IT needs as one large category.

Suddenly, your buying power skyrockets. When you bundle your needs, you can negotiate much better volume discounts, lock in more favorable contract terms, and simplify your supplier landscape. This doesn't just cut down on direct spending; it also eases the administrative headache of juggling dozens of different vendors and contracts.

Analyzing Your Spending to Find Opportunities

Before you can save, you need to know exactly where your money is going. The first real step is to dive deep into your spending data to see the patterns and identify your largest purchasing categories.

And don't just focus on the obvious big-ticket items. I've often seen the most significant savings hiding in smaller, frequent purchases that quietly add up over time.

- Office Supplies: Are different teams buying pens and paper from various retailers, completely missing out on bulk pricing opportunities?

- Software Subscriptions: How many redundant licenses are you paying for? Are there underused tools that could be consolidated or cut entirely?

- Maintenance Services: Could you get a better rate by bundling all your facility maintenance needs with a single, trusted provider instead of using multiple contractors?

When you group these related buys, you can walk into a negotiation from a position of real strength, leveraging your company's total spend.

It's not just theory; strategic category management is a proven cost-reduction engine. I've seen firsthand how developing targeted purchasing strategies for specific categories helps companies achieve 10-15% cost savings in procurement alone. You can learn more about these powerful procurement strategies from Concord and see the data for yourself.

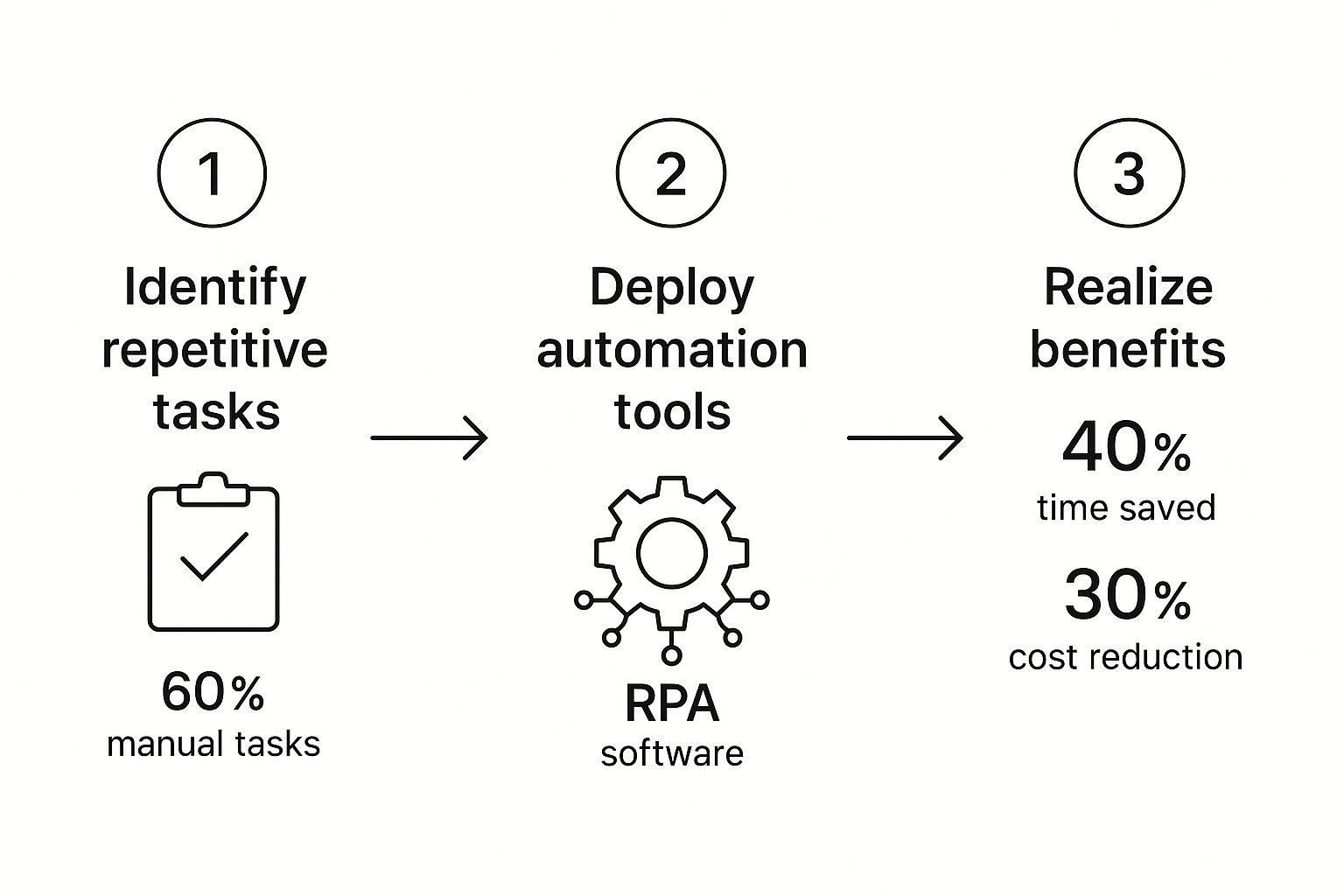

The infographic below gives a great visual of how modernizing your procurement through automation can directly lead to savings.

As you can see, simply identifying manual tasks and applying automation can streamline your entire workflow, which translates directly into time and money saved.

Building a Sourcing Plan That Works

Once you've mapped out your key spending categories, it's time to build a sourcing plan that actually delivers results. This means looking past the sticker price and thinking about the total cost of ownership.

A perfect real-world example is buying vehicles for a commercial fleet. The initial purchase price is just one small part of the story. Our own electric vehicle cost comparison dives into how factors like fuel (or electricity), ongoing maintenance, and available tax incentives paint a completely different financial picture over the vehicle's life.

This is the difference between a tactical purchase and a strategic one. Take a look at this comparison:

Traditional vs Strategic Procurement

| Aspect | Traditional Procurement | Strategic Category Management |

|---|---|---|

| Focus | Price & immediate needs | Total cost of ownership & long-term value |

| Approach | Reactive, transactional | Proactive, relationship-based |

| Decision-Making | Decentralized, department-level | Centralized, data-driven |

| Supplier Relations | Many suppliers, adversarial | Fewer strategic partners |

| Outcome | Short-term cost savings | Sustainable value & efficiency |

The table really highlights the fundamental shift. Moving to a strategic model isn't just about saving a few dollars today; it's about building a more resilient, efficient, and cost-effective operation for the long haul. A cheaper piece of equipment that constantly breaks down will always cost you more in downtime and repairs than a slightly more expensive but reliable alternative. That's the strategic difference.

Rethink Your Physical and Energy Footprint

Your buildings and the energy they consume are massive, often overlooked, opportunities for serious savings. It's easy to let costs for rent, utilities, and maintenance spiral out of control. But with the recent shifts in how we work, it’s the perfect time to ask a critical question: what do we really need from our physical spaces?

The move toward hybrid and remote work isn't just a cultural shift; it's a massive financial lever you can pull. We've seen countless businesses realize they can maintain, and sometimes even boost, productivity with a much smaller office. This opens the door for strategic downsizing, which immediately cuts down on big-ticket items like rent, property taxes, insurance, and daily utility usage.

The post-pandemic world has proven that flexible work arrangements can lead to serious savings. In fact, some studies show that businesses adopting a hybrid model have been able to cut their fixed costs by as much as 20-30%. By getting smart about office space, companies have slashed their real estate footprints, which for larger enterprises, can mean saving millions of dollars every single year. You can discover more insights about these cost-reduction strategies for 2025.

Get Smart About Saving Energy

Beyond real estate, your day-to-day energy consumption is another goldmine for savings. Even if your entire team is on-site, a few intelligent adjustments can make a huge dent in your monthly utility bills. The goal here is to cut out the waste without impacting anyone's performance.

These aren’t complicated, expensive overhauls. They are practical, high-impact changes:

- Swap to LED Lighting: This is one of the fastest and easiest wins. Moving from old-school fluorescent or incandescent bulbs to modern LEDs can cut your lighting energy use by up to 75%. Plus, they last up to 25 times longer, so you save on maintenance and replacement costs, too.

- Install Smart Thermostats: Stop heating and cooling an empty building. A programmable or smart thermostat can automatically adjust the temperature based on your actual work hours, shutting things down on weekends and holidays. You only pay for the climate control you actually use.

- Run an Energy Audit: You can't fix what you don't measure. A professional energy audit is great, but even a simple DIY walkthrough can pinpoint where your energy is going. You might find drafty windows, inefficient old equipment, or "vampire" appliances that suck power even when they're turned off.

The real shift in thinking is to see energy not as a fixed, unavoidable cost, but as a variable that you have direct control over. Every kilowatt-hour you save drops straight to your bottom line, and those savings add up month after month.

Thinking creatively about your space can also lead to savings. For example, a good skylight energy efficiency guide to cut energy bills can show you how to maximize natural light, which not only reduces lighting costs but can also help with heating and cooling.

Take a Hard Look at On-Site Energy Use

Optimizing your energy strategy also means looking at the equipment you run on-site, especially your vehicle fleet. If you manage a large campus, a resort, or a planned community, the energy needed to run your maintenance, security, or transport vehicles can be a huge expense. It’s an area you can’t afford to ignore.

For instance, how you charge your electric vehicles can have a surprising impact on your energy bills. Simply shifting your charging schedule to off-peak hours, when electricity rates are at their lowest, is a simple but incredibly effective strategy. Our guide on EV charging efficiency dives much deeper into this, offering practical tips to get the most out of your power while keeping costs down.

Ultimately, every small adjustment—from the lightbulbs in the ceiling to the way you charge your vehicles—adds up to a more efficient, sustainable, and profitable operation.

Future-Proof Your Fleet and Slash Fuel Costs

If your business relies on a vehicle fleet, you know that fuel and maintenance costs can feel like a runaway train. These expenses are a constant drain on your profit margins, and they spike every time gas prices do. Many companies just accept this as the cost of doing business, but there's a much smarter way to operate.

Moving to electric vehicles (EVs) is more than just a green initiative—it's one of the most powerful financial moves you can make. The real win isn't just about ditching the gas pump. To see the full picture, you have to look at the total cost of ownership (TCO).

The True Cost of Vehicle Ownership

When you put an EV head-to-head with a traditional gas vehicle, that initial sticker price is just the beginning of the story. The real savings kick in the second your drivers get behind the wheel.

Let’s start with the obvious: fuel. Electricity is just flat-out cheaper than gasoline, and its price is far more stable. A full charge for a commercial EV can cost just a few dollars, a tiny fraction of a fill-up at the pump. When you multiply that by a fleet of vehicles running daily, the savings are staggering.

Then you have maintenance, or rather, the lack of it. EVs are mechanically simple, with far fewer moving parts than a combustion engine. This translates directly to money saved.

- No more oil changes. Gone. Forever.

- Fewer parts to fail. Forget about replacing spark plugs, fuel filters, or entire exhaust systems.

- Longer brake life. EVs use regenerative braking to slow down, which puts less wear and tear on your brake pads and rotors.

When you combine the dramatically lower "fuel" costs with minimal maintenance needs and factor in government incentives, the TCO for an EV crushes its gas-powered equivalent. That initial investment starts paying for itself much faster than you might think.

Smart Management Is Key to Unlocking Savings

Just buying the vehicles is only half the battle. To truly slash your operational costs, you need to pair your EV fleet with modern fleet management software. Think of it as the brain of your operation, constantly turning raw data into real-world savings.

Good software gives you the tools to fine-tune every part of your fleet's performance. For example, it can map out the most efficient routes based on traffic and job sites, which cuts down on wasted energy and gets your team where they need to be faster. For a deeper dive, check out our guide on fleet management best practices.

This technology is also your secret weapon for managing charging. The software can automatically schedule vehicles to charge during off-peak hours when electricity is cheapest, a simple adjustment that can make a huge dent in your utility bills. It also keeps an eye on vehicle health in real-time, alerting you to small issues before they turn into a costly breakdown that sidelines a vehicle.

Investing in EVs and the right management tools is a direct investment in a more predictable and profitable future. You aren't just buying new trucks; you're insulating your business from volatile fuel markets and building a leaner, more reliable operation from the ground up.

Common Questions About Cutting Operational Costs

As you start looking for ways to trim your operational costs, you're bound to have some questions. It's only natural. Let's walk through some of the most common concerns I hear from business leaders so you can move forward with confidence.

A big one is the fear that cutting costs automatically means sacrificing quality or hurting team morale. But that's not the goal here. We're talking about boosting efficiency, not just slashing budgets. Think about it: automating a repetitive, manual task doesn't lower quality. It actually frees up your people to focus on more important work that improves it.

Then there's the question of upfront investment. "Do I need a huge budget to start seeing savings?" Absolutely not. Sure, big moves like transitioning to an EV fleet have an initial price tag, but many of the most effective strategies are low-cost or even free. A simple energy audit or consolidating a few software subscriptions just takes a bit of time and focus, not a pile of cash.

Where’s the Best Place to Start?

The best place to start is always where you have the most data and the most control. For most businesses, that points directly to procurement and energy consumption. Your spending data is a goldmine, and a quick look will often reveal easy opportunities to consolidate vendors or renegotiate contracts for some quick wins.

Energy use is another tangible expense you can tackle right away. Simple changes here offer a fast return and help build momentum for bigger projects down the road.

- Dig into your top five expense categories. Look for any overlap or areas where you can use your purchasing volume to get a better price.

- Do a walkthrough of your facility after hours. You might be surprised by how much energy is wasted on lights or equipment left running overnight.

- Chat with your frontline employees. They see the day-to-day inefficiencies firsthand. Ask them what drives them crazy—their insights are pure gold.

The real secret isn't finding one magic bullet. It's about making a series of smart, incremental changes across the board. The combined impact of all those small adjustments is what creates massive, lasting cost reductions.

How Long Until I Actually See a Return?

This really depends on the strategy. If you renegotiate a supplier contract, you could see the savings on your very next invoice. The same goes for something like switching to LED lighting—that will show up on your next utility bill.

Bigger investments, like a new automation system or transitioning your fleet to electric vehicles, will naturally have a longer payback period. But the long-term savings on things like fuel, maintenance, and labor are often so significant that they become a critical part of any forward-thinking strategy. It’s all about balancing those quick wins with strategic, long-term investments.

Ready to future-proof your fleet and dramatically cut your fuel and maintenance expenses? Explore the powerful, efficient, and street-legal vehicle lineup from Solana EV and discover how our electric solutions can drive down your total cost of ownership. Visit us at https://solanaev.com to learn more.