Think of golf cart safety training as the essential education that teaches people how to properly inspect, handle, and drive these vehicles. The goal is simple: prevent accidents and injuries. For any organization that relies on golf carts, this isn't just a "nice-to-have." It’s about creating a deep-seated understanding of what these machines can—and can't—do, and how to navigate the hazards of the real world.

Why You Can’t Afford to Skip Golf Cart Safety

It's tempting to look at a golf cart and see it as a harmless, oversized toy. Perfect for a relaxed ride around a resort or a quick trip across campus, right? Unfortunately, this casual attitude is exactly what makes them so dangerous. The reality is, these vehicles are central to thousands of preventable accidents every year, many with devastating outcomes.

This is where a solid golf cart safety training program comes in. It’s far more than a box-ticking exercise; it’s a core part of building a proactive safety culture. It shifts an operator's perspective from casual to cautious, giving them the skills to spot and handle risks before they turn into incidents. Good training directly protects your people, your visitors, and your bottom line by cutting down on liability and preventing expensive accidents.

The Numbers Tell a Sobering Story

The data on golf cart incidents is eye-opening. A major study found that from 1990 to 2006, U.S. emergency rooms treated 147,696 injuries related to golf carts. That’s nearly 8,700 injuries every single year, with the incident rate jumping by over 132% during that period.

Perhaps the most telling statistic? A shocking 38.3% of those injuries happened when a passenger simply fell out of the moving cart. This detail, found in the original research, highlights a common but incredibly severe hazard that proper training can easily address.

"People see golf carts as easy to drive, but they forget these vehicles have no doors, no reinforced roofs, and no airbags. The only 'safety feature' that can adapt to any situation is a well-trained operator."

This isn't about scaring anyone. It's about building a healthy respect for the machine. A well-designed training program gives you, the safety manager, the facts and real-world examples you need to build a program that goes beyond simple compliance to create true competence.

Common Golf Cart Hazards and Their Real-World Consequences

To prevent accidents, you first need to know where things typically go wrong. I’ve seen firsthand how a simple oversight can lead to a serious incident, whether it's on a quiet residential path or a busy industrial site. Effective golf cart safety training hones in on these high-risk behaviors and environmental traps.

The table below breaks down some frequent risks I've encountered and what can happen, showing exactly where targeted training makes the biggest difference.

| Hazard Type | Common Scenario | Potential Consequence |

|---|---|---|

| Uneven Terrain | Driving too fast over a grassy hill or hitting an unseen pothole. | Loss of control, vehicle rollover, or passenger ejection. |

| Passenger Behavior | Standing up while the cart is moving or not holding on. | Falling out during a turn, leading to fractures or head injuries. |

| Overloading | Exceeding the vehicle’s passenger or weight limit. | Brake failure on slopes, instability, and a much higher risk of tipping. |

| Pedestrian Areas | Navigating crowded walkways without alerting people. | Collisions with pedestrians, causing serious harm to others. |

| Poor Maintenance | Using a cart with low tire pressure or worn-out brakes. | Unpredictable handling, poor stopping power, or total equipment failure. |

Every single one of these scenarios is avoidable. The key is to build a culture where safety isn't just assumed but is actively practiced by everyone, starting with thorough operator training. That is the fundamental purpose of any successful golf cart safety program.

Building Your Program Foundation

A truly effective golf cart safety training program doesn't start in the classroom. It begins with a deep dive into your specific operational environment. Let’s be honest, a generic, one-size-fits-all plan just won't cut it. The risks on a sprawling university campus are worlds away from those in a gated community or a busy industrial complex.

The first, most critical task is a thorough needs analysis of your site. This means walking the actual routes your drivers will use and seeing the environment through the lens of risk management. What are the unique hazards they'll face every day?

For instance, a resort might have high-traffic crosswalks teeming with pedestrians near the main entrance. A manufacturing facility, on the other hand, could have blind corners where a golf cart and a forklift might unexpectedly meet. Identifying these real-world challenges is what allows you to build a program that actually works.

Turning Vague Rules Into Clear Objectives

Once you've mapped out your specific hazards, it's time to turn broad safety guidelines into clear, measurable training objectives. Simply telling someone to "drive safely" is vague and impossible to train or enforce. You need to create concrete goals that define what success actually looks like.

This is where you translate abstract principles into tangible skills. A strong objective is something you can see, measure, and evaluate, moving your training from a lecture to a hands-on, skills-based session.

Here's how to reframe those common rules into specific goals:

-

Instead of: "Check the cart before use."

-

Try: "Operators will demonstrate a complete 360-degree walk-around inspection, correctly identifying the location and function of all safety components."

-

Instead of: "Be careful on hills."

-

Try: "Operators can successfully navigate a 15-degree incline and decline without losing control or compromising vehicle stability."

These objectives become the core of your curriculum and the benchmark for your final skills test. They set a clear standard for everyone involved.

Integrating Visual Safety Cues

Your training program can't live in a bubble; it needs to be reinforced by the physical environment. Visual cues are crucial for keeping the lessons from your training sessions top-of-mind during daily operations.

To make your program stick, think about how effective workplace safety signs can bolster your rules and visually flag hazards for both drivers and pedestrians. These signs act as constant, silent reminders.

A well-placed 'Stop Before Exiting' sign at a blind corner or a 'Yield to Pedestrians' marker in a busy area can prevent an accident long after the formal training session has ended. They are silent partners in your safety program.

This integrated approach ensures the principles taught in your course are consistently applied in the real world. Of course, the condition of the carts themselves is a huge piece of this puzzle. A program that preaches pre-trip inspections is seriously undermined if the vehicles are in poor shape.

You can learn more about building a solid inspection routine in our guide to https://solanaev.com/golf-cart-maintenance/. A well-maintained fleet sends a powerful message that safety is a priority from the ground up, completing the foundation for a true culture of safety.

Crafting Your Core Training Curriculum

Now that you've laid the groundwork, it's time to dig into the heart of your program: the training curriculum itself. This is where you equip your operators with the specific skills and knowledge they need to stay safe and prevent accidents.

A truly effective curriculum goes way beyond just handing out a list of rules. It’s about building real-world competence and muscle memory. The goal is to create materials that are not just informative but genuinely engaging and easy to recall under pressure—think visual aids, quick-reference checklists, and practical scenarios that stick.

This isn’t just best practice; it’s a critical risk management step. Between 2012 and 2021, golf cart accidents were responsible for over 1,000 major orthopedic injuries, including severe fractures and even amputations. A major contributing factor is the patchwork of regulations from one town to the next, which is why a standardized, high-quality internal training program is so essential. You can see more on these findings on golf cart injury trends for a clearer picture of the risks.

Essential Training Module Checklist

Every golf cart safety curriculum needs to be built on a solid foundation of non-negotiable topics. Think of these as the absolute must-haves. Below is a checklist of core modules that ensure every operator, new or experienced, is on the same page.

| Module | Key Learning Points | Suggested Training Method |

|---|---|---|

| Pre-Operation Inspection | Brakes, steering, tire condition, battery, lights, and horn. The goal is a consistent, repeatable walk-around. | Hands-on demonstration followed by a required daily checklist submission. |

| Vehicle Dynamics & Controls | High center of gravity, braking distance on wet vs. dry surfaces, turning radius, and acceleration quirks. | Closed-course driving drills focusing on sudden stops and sharp turns. |

| Situational Awareness | Scanning for pedestrians, blind corners, and other vehicles. Defensive driving principles tailored to a cart. | Scenario-based discussions and videos showing common "close call" situations. |

| Site-Specific Rules & Hazards | Designated travel paths, speed limits, no-go zones, and unique environmental risks (e.g., steep hills). | Site map review, followed by a guided tour of the actual routes. |

| Emergency Procedures | What to do in case of a tip-over, brake failure, or medical emergency. | Role-playing exercises and clear, documented protocols. |

Covering these five areas thoroughly gives you a robust program that moves operators from simply knowing the rules to understanding why they matter and how to apply them.

Building Scenarios That Actually Teach

To make the training memorable, you have to move beyond dry lectures. The best way I’ve found to do this is by building realistic training scenarios that force operators to think on their feet.

A good scenario isn’t complicated. It just needs three parts: the setup, the conflict, and the correct resolution.

Here’s a simple one I use for warehouse environments:

- Setup: An operator is driving a cart down a main aisle. Up ahead, a forklift is reversing out of a connecting aisle.

- Conflict: The forklift’s beeper is faint over the warehouse noise, and the driver's view is partially blocked. The cart operator is approaching the intersection a bit too fast.

- Correct Resolution: The cart operator slows way down before the intersection, makes eye contact with the forklift driver to confirm they’ve been seen, and yields the right-of-way. They wait until the forklift is completely clear before moving on.

This approach transforms a simple rule like "yield to heavy equipment" into a powerful, practical lesson that an operator will actually remember.

Expert Tip: The key to a great curriculum is realism. Instead of just saying, "Be careful near pedestrians," create a specific scenario: "You need to navigate past the main resort pool entrance right as a large group is leaving." The more specific the story, the more memorable the safety lesson.

Of course, operator skill is only one half of the equation. Even the most well-trained driver can’t prevent an accident caused by a mechanical failure. This is why the pre-use inspection is so critical. For a closer look at what goes into keeping your fleet in top shape, our guide on essential electric vehicle maintenance is a great resource. After all, your carts need to be just as ready for the job as your drivers are.

Putting Skills to the Test with Hands-On Evaluations

Theory is one thing, but the real proof of a solid golf cart safety training program is seeing it in action. This is where we move from the classroom to the pavement, where operators have to show they can do more than just recall the rules. They need to demonstrate real competence behind the wheel.

A hands-on evaluation isn't just a box to check; it’s the single most important step to confirm someone can safely operate a vehicle in your actual work environment. A well-planned practical course is what connects knowing what to do with having the muscle memory to pull it off when it counts.

The whole point is to simulate the unique challenges of your site. You'll want to set up a closed course that pushes operators to prove they can steer with precision, brake with confidence, and stay in control during the very situations they'll face every day. This is how you ensure certification is truly earned through skill, not just attendance.

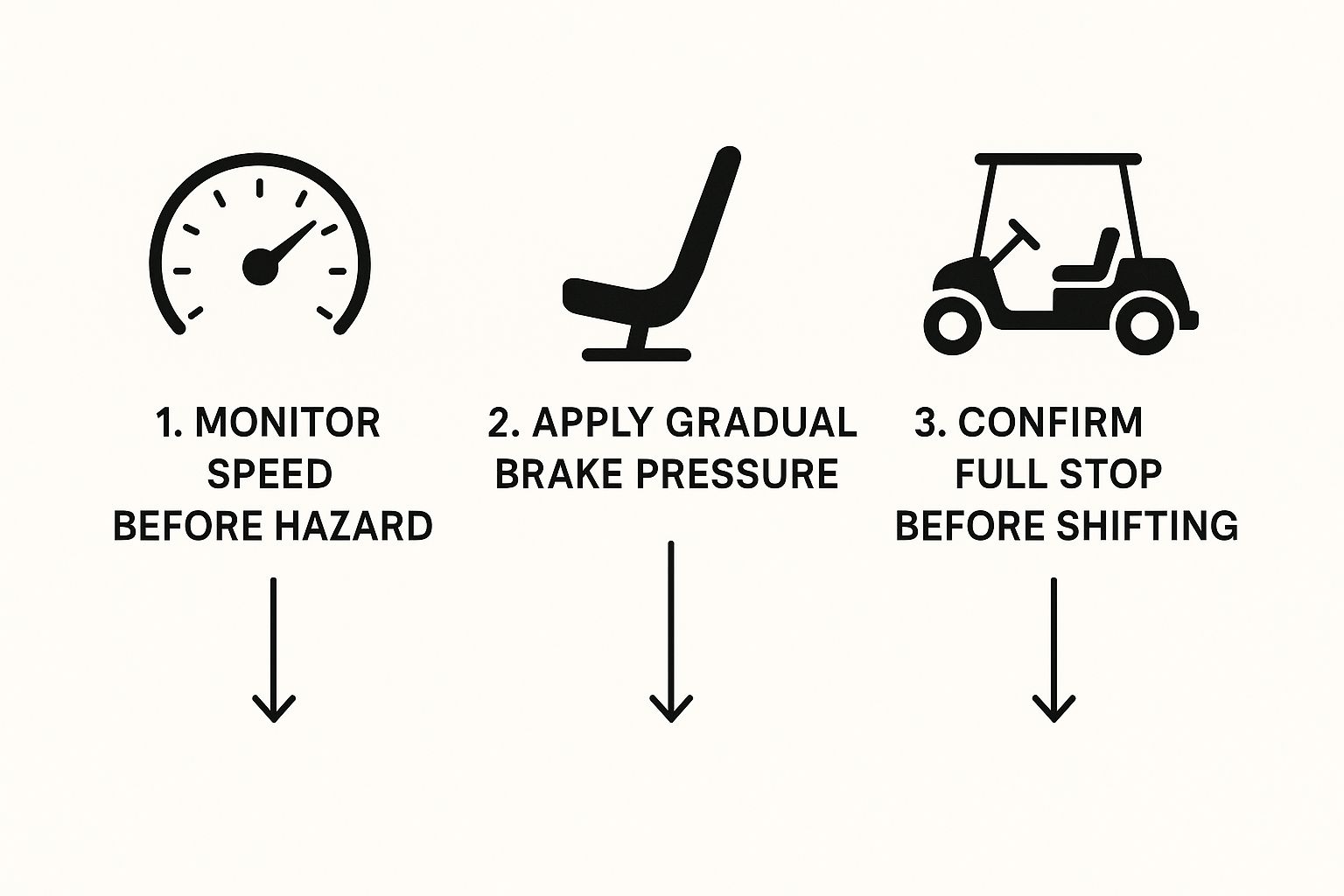

This image really drives home the fundamental thought process every operator needs when they encounter a potential hazard on their path.

It breaks down the act of braking into three distinct, logical steps. This reinforces that a safe stop is a calculated process, not just a frantic, last-second reaction.

Designing Your Practical Driving Course

First things first, you need to design a course that builds and tests the core skills. You don't need a huge, dedicated space for this—a quiet corner of a parking lot is often perfect. The trick is to set up drills that are both challenging and directly related to what your drivers will be doing on the job.

Here are a few essential drills I always include:

- Slalom Course: Set up a line of cones just far enough apart to make it tricky. This is a fantastic test of an operator's ability to make smooth, controlled steering inputs without lurching or hitting anything. It quickly shows you if they have a good feel for the cart's turning radius.

- Emergency Braking: Mark a starting line and a "stop box" a bit further down the course. Have the operator get up to a normal speed for your site, then brake firmly to come to a complete stop inside the box. This drill is all about reaction time and understanding how far the cart will travel before stopping on that specific surface.

- Backing and Parking: Create a simulated parking spot. The operator's task is to reverse into the space using only their mirrors and looking over their shoulder, finishing up straight and centered. This is an absolutely critical skill for navigating tight or crowded areas.

These exercises cover the basic mechanics of safe cart operation. Just make sure to walk through the purpose of each drill before they start.

Using a Skills Checklist for Fair Evaluation

Vague feedback like, "You did great," just doesn't cut it. To make your evaluation process consistent, fair, and easy to document, you need an objective way to score performance. A detailed skills checklist is the best tool for the job. It breaks down every task into specific, observable actions you can grade against a clear standard.

This approach takes all the guesswork out of the equation and guarantees every operator is assessed using the same criteria.

A great skills checklist goes beyond the final outcome. It evaluates the process. For instance, instead of just asking, "Did the operator stop in time?" it should include checkpoints like, "Did the operator check their surroundings before braking?" and "Was the stop controlled and in a straight line?"

Here’s a simple structure you can adapt for your own checklist:

| Task Assessed | Performance Standard | Pass/Fail | Notes/Comments |

|---|---|---|---|

| Figure-Eight Turns | Maintained a steady speed; didn't hit any cones; steering was smooth. | ||

| Navigating Inclines | Drove up and down the ramp without sudden speed changes or jerking. | ||

| Pedestrian Awareness | Slowed down and made eye contact with the simulated pedestrian. | ||

| Post-Operation Securement | Set the parking brake; removed the key; did a final walk-around. |

This level of detail gives you concrete data on an operator's true abilities. It also builds a valuable training record, which is essential for compliance and helps you pinpoint exactly where someone might need a little extra coaching. When you combine realistic driving drills with an objective checklist, you create a powerful evaluation that genuinely validates an operator’s readiness.

Managing Certification and Ongoing Training

A great golf cart safety training program doesn't stop once the final test is passed. That’s actually where the real work begins. To build a true safety culture that sticks, you need a solid system for certification and a commitment to ongoing training.

Handing an operator a formal certification does more than just check a box. It elevates the training from a one-time class to an official qualification. It sends a clear message: driving a company cart is a serious responsibility, not just a given perk. If you're building a program from the ground up, it's worth looking into tips on how to create a robust certification program to ensure it reinforces high standards and builds trust from day one.

Establishing a System for Certification and Recertification

An operator's certification shouldn't be good for life. Over time, even the best drivers can get a little complacent and good habits can fade. That's why a structured recertification schedule is non-negotiable.

So, how often should you recertify? For most places, requiring operators to renew their certification every one to three years is the sweet spot. A bustling resort with heavy cart traffic might lean towards the one-year mark, while a quieter facility could comfortably go with three. The key is to match the cycle to your specific risks.

A good system needs a few core components:

- A Centralized Record: Keep a simple database or even a well-organized spreadsheet. Log everyone who is certified, when they were trained, and when their renewal is due.

- Clear Expiration Policies: Nobody should have to guess. Make sure every operator knows exactly when their certification expires and the steps to get it renewed.

- Automatic Reminders: Don't rely on memory. Set up calendar alerts or automated emails to ping both the operator and their supervisor 30-60 days before their certification is up.

This simple framework creates accountability and makes sure no one slips through the cracks. It subtly reinforces that safety isn't a one-and-done deal—it's a constant expectation.

An operator's certification card should be more than just a piece of plastic. Make it a tool. List the specific types of carts they're cleared to drive and, most importantly, the expiration date. It becomes a physical, professional reminder of their responsibility every time they see it.

Transforming Incidents into Learning Opportunities

Let's be realistic: no matter how airtight your training is, incidents and near-misses can still occur. The mark of a truly effective safety program is what you do when they happen. Every single event, from a fender bender to a close call, is a golden opportunity to learn and improve.

A post-incident review should never be about pointing fingers. The goal is to uncover the why. You have to dig into the operator's actions, the vehicle's condition, and the environment. Was the pre-use inspection checklist actually completed? Was a blind corner a factor? This is also where investing in quality vehicle care proves its worth. For instance, a properly maintained cart is far less likely to be the root cause of an issue. Our guide on golf cart battery maintenance shows how simple upkeep plays a huge role in overall safety.

The lessons you pull from these reviews must be fed directly back into your training program. If a near-miss happens at a tricky intersection, that specific scenario should become a focal point in your next hands-on refresher course. This continuous feedback loop is what shifts your culture from being reactive to truly proactive, stopping the same mistakes from happening over and over again.

Answering Your Team's Top Golf Cart Safety Questions

Even with the best-laid training plan, you're going to get questions. That's a good thing—it means people are engaged. Anticipating and answering these common queries is key to making sure your entire team, from operators to managers, is on the same page.

Think of this as your field guide for those nagging little questions that can make or break a safety program. Let's clear up some of the most frequent points of confusion.

How Often Do We Need to Do This Training?

This is easily the number one question I hear. The short answer is: it depends. First things first, every single employee must go through your full, comprehensive training program before they ever get behind the wheel of a cart. That part is non-negotiable.

After that initial training, federal rules are very specific about when you must retrain someone. An operator needs to be retrained if they're involved in an accident or even a near miss. It's also required if you or a supervisor sees them driving irresponsibly—maybe they're taking corners on two wheels or texting while driving. The final trigger for mandatory retraining is when you introduce a different type of cart that handles in a completely new way.

As a best practice, don't just wait for something to go wrong. The safest companies I've worked with recertify every single operator every 1-3 years. It’s a proactive way to keep skills fresh and fight off the bad habits that creep in over time.

You can also reinforce good habits without a full-blown training day. Quick "toolbox talks" or brief safety huddles are perfect for going over a specific rule or discussing something that was recently observed on site.

Can We Just Do the Training Online?

In a word: no. While online courses and videos are fantastic for covering the "book smarts" of golf cart safety, they only get you halfway there. They’re great for teaching the rules of the road and the theory behind vehicle operation, but they can't prove a driver actually knows what they're doing.

The Occupational Safety and Health Administration (OSHA) is crystal clear that training must include a hands-on, practical evaluation. This means a qualified person has to physically watch the employee operate the cart in the exact environment where it will be used.

This hands-on portion is critical for a few reasons:

- It proves they can apply the knowledge: Can they actually brake smoothly, handle tight corners, and react safely to pedestrians?

- It accounts for your specific site: It shows they can navigate your facility's unique challenges, like blind intersections or steep loading ramps.

- It builds muscle memory: There’s no substitute for the physical act of doing safety checks and driving drills to make them second nature.

A truly effective program always blends classroom-style learning (which can be online) with a supervised, in-person driving test.

What Should Be on Our Daily Inspection Checklist?

The daily pre-use inspection is your first line of defense against an accident caused by equipment failure. The checklist needs to be thorough enough to catch real problems but quick enough that it doesn't get skipped.

Operators must be trained to ground any cart that fails an inspection and immediately report it to a supervisor. That cart stays out of service until it's been repaired and officially cleared.

Here are the non-negotiables for any daily checklist:

- Tires and Wheels: Check for proper inflation, any cuts or damage, and make sure lug nuts are tight.

- Brakes: Test the foot brake to see how it responds and set the parking brake to make sure it holds the cart securely.

- Steering: The wheel should feel tight and responsive, not loose or wobbly.

- Safety Alarms: Give the horn a quick toot and check the reverse beeper (if equipped) to ensure they’re loud enough.

- Battery: Glance at the charge level and look for any corrosion or leaks around the terminals.

- Safety Features: If the cart has lights, mirrors, or seatbelts, make sure they’re all there and working correctly.

This simple two-minute walk-around is one of the most powerful safety habits you can build.

Who Can Actually Be a Golf Cart Safety Trainer?

This is another area where the rules provide some flexibility, but the spirit of the law is obvious. OSHA states that a trainer must have the necessary knowledge, training, and experience to teach operators and judge their abilities.

This doesn't mean they need a fancy "train-the-trainer" certificate, although those courses are certainly helpful. It means your designated trainer has to be a genuine expert on the topic.

Usually, this person is an experienced supervisor, a trusted lead operator, or a safety manager who has a deep understanding of:

- The specific golf cart models you use on-site.

- The unique hazards and travel routes at your facility.

- All company safety policies and federal regulations.

- How to communicate clearly and give constructive, helpful feedback.

Bottom line: you can't have someone lead the training if they've only read the manual. Your trainer needs to be able to confidently answer tough questions, demonstrate the right way to do things, and make an accurate call on whether an operator is truly safe enough to be handed the keys.

At Solana EV, we believe that a well-trained operator is the most important safety feature on any vehicle. Our commitment to performance and reliability is matched by our dedication to promoting safe operation for every customer, from resort managers to individual owners. Discover how our street-legal electric vehicles are engineered for superior safety and handling. Explore our premium lineup.